When addressing recyclability and waste management for PVC finished products, there are several key areas to focus on due to the complexity of recycling PVC and its potential environmental impact. Here’s what to pay attention to:

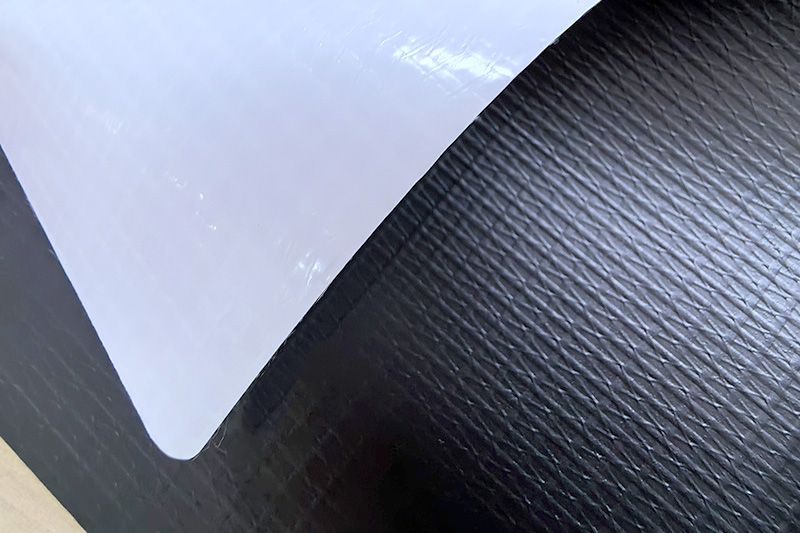

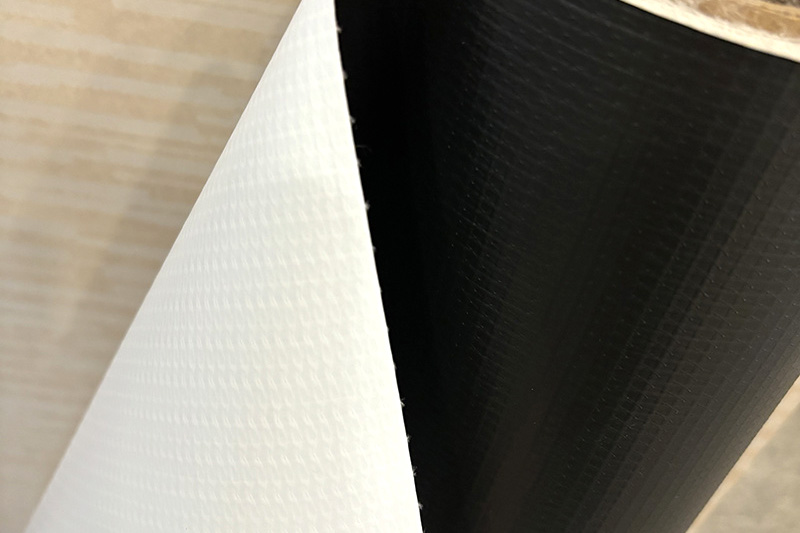

Unlike some other plastics, PVC (Polyvinyl Chloride) has a complex recycling process due to the additives, such as plasticizers, stabilizers, and pigments, used to give it specific properties like flexibility, durability, or color. These additives often make it difficult to recycle PVC through conventional methods.Many recycling facilities are not equipped to handle PVC. This is because PVC recycling requires more specialized processes compared to other plastics like PET or HDPE.

PVC can be recycled mechanically, where it is cleaned, shredded, and reprocessed into new products. However, this process degrades the material quality, limiting its recyclability. Chemical recycling, which breaks down PVC into its base components, offers better potential but is not widely available due to high costs and technical challenges.PVC often contains mixed materials (e.g., in composite products like windows or flooring), and this contamination further complicates recycling efforts.

Unlike more common plastics, PVC recycling requires specialized infrastructure. In many regions, the availability of facilities that can process PVC is limited.The availability of PVC recycling options varies depending on the location. Some countries or municipalities may have better recycling systems in place, while others may not recycle PVC at all. Ensuring that there are accessible recycling programs is crucial to reducing landfill waste.

Some manufacturers or industries have initiated take-back or recycling programs for specific PVC products, such as pipes or flooring. These programs can help reduce waste by ensuring that PVC products are collected and recycled efficiently.

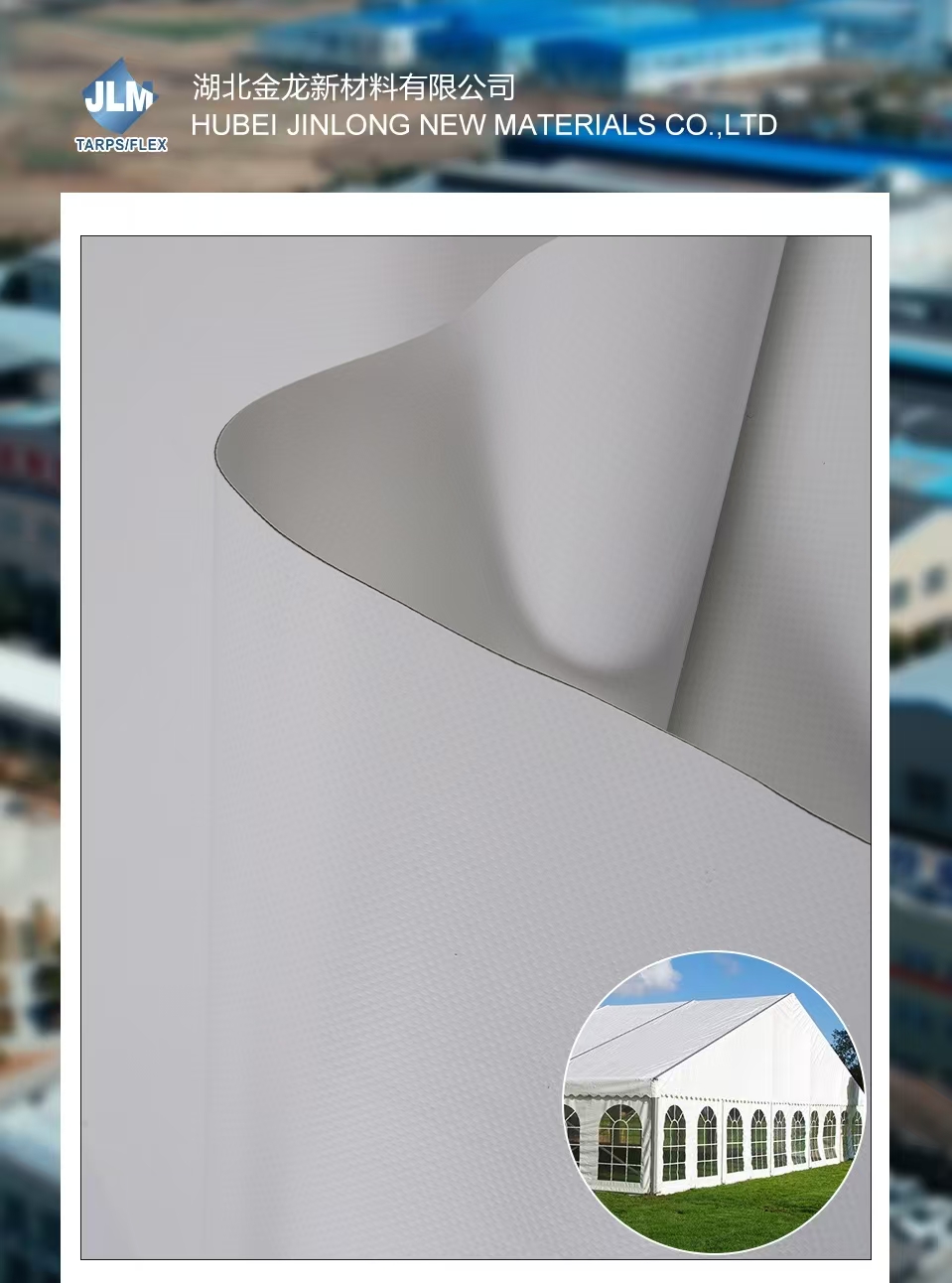

Rigid PVC (used in pipes, window frames, etc.) is easier to recycle than flexible PVC (used in packaging, hoses, etc.) due to fewer additives. Understanding the different recycling requirements for these types is important when planning waste management strategies.During recycling, PVC is sensitive to heat and can degrade quickly. This thermal sensitivity makes the recycling process challenging and limits the number of times PVC can be recycled without losing its properties.

When PVC is not recycled, it often ends up in landfills, where it can take centuries to degrade. Over time, PVC can leach harmful chemicals into the surrounding environment, including phthalates and dioxins, which can contaminate soil and groundwater.As PVC degrades slowly, it can break down into microplastics, which are a growing environmental concern. These tiny particles can enter ecosystems and harm wildlife.

When PVC waste is incinerated, it can release toxic gases such as hydrogen chloride and dioxins, which are hazardous to both human health and the environment. Ensuring that PVC waste is not incinerated is critical to reducing air pollution and toxic emissions.

One of the most important focuses should be on designing PVC products that are easier to recycle. This could involve reducing the use of harmful additives, simplifying product composition, and making products more suitable for recycling.Encouraging the production of mono-material PVC products (made entirely of PVC without mixing other materials) can improve recyclability and make waste management easier.

Efficient waste management systems rely on proper collection and sorting of PVC materials. Implementing better waste segregation systems that identify and separate PVC from other waste streams can improve recycling rates.

Educating consumers on how to properly dispose of PVC products can improve collection rates. Providing information about local recycling options or encouraging participation in take-back programs can reduce the amount of PVC sent to landfills.

Developing and investing in chemical recycling technologies that can break down PVC into its base components (chlorine, carbon, and hydrogen) could drastically improve the material's recyclability. This method can potentially turn PVC waste into new, high-quality materials without the degradation seen in mechanical recycling.Some industries are working towards closed-looprecycling systems where waste from one product is used as raw material for new products. This circular approach reduces the need for virgin PVC production and minimizes waste.

Focusing on the recyclability and waste management of PVC finished products requires addressing the challenges in recycling infrastructure, enhancing product design for recyclability, minimizing harmful disposal practices, and supporting innovative recycling technologies. By improving waste management strategies and encouraging the development of sustainable alternatives, the environmental impact of PVC can be significantly reduced.

English

English русский

русский Français

Français Español

Español