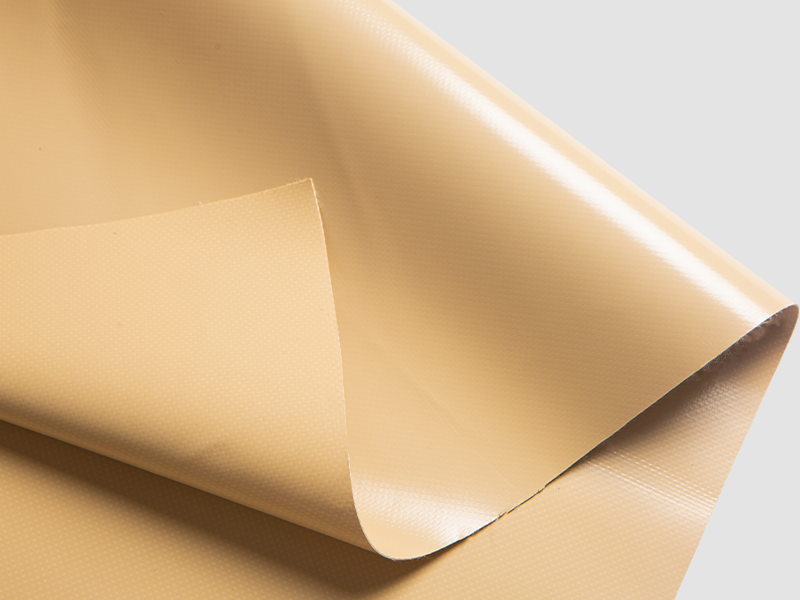

The PVC coating is fundamental to the waterproof function of PVC tarpaulin. Here’s how it ensures the fabric remains impervious to water:

The PVC coating forms a continuous, impermeable layer over the polyester base fabric. This layer prevents water from seeping through the fabric, effectively making the tarpaulin waterproof.

The coating also helps seal seams and edges where the fabric might otherwise be vulnerable to water penetration.

The PVC coating is applied evenly across the fabric, ensuring that no gaps or thin spots are present where water could potentially penetrate.The PVC adheres strongly to the polyester fibers, creating a robust barrier that resists water infiltration.

PVC has inherent hydrophobic properties, meaning it repels water. When applied as a coating, these properties enhance the tarpaulin's ability to resist water absorption and prevent it from soaking through.The surface of the coated tarpaulin causes water to bead up and roll off rather than penetrating the fabric.

The coating protects the underlying polyester fabric from water damage, such as rot or mildew, which can occur if water were allowed to penetrate.The PVC surface is easy to wipe clean, as water and other liquids do not easily penetrate or stain the fabric.

The uniformity and integrity of the PVC coating maintain its waterproof performance over time, ensuring the tarpaulin remains effective in protecting against moisture for its intended lifespan.

The PVC coating provides a reliable waterproof function by forming a protective, hydrophobic barrier that keeps water from penetrating through to the underlying fabric. This characteristic is crucial for maintaining the functionality and longevity of PVC tarpaulin in various applications where moisture protection is essential.

English

English русский

русский Français

Français Español

Español