The durability and service life of PVC Inflatable Fabric are mainly guaranteed by the following aspects:

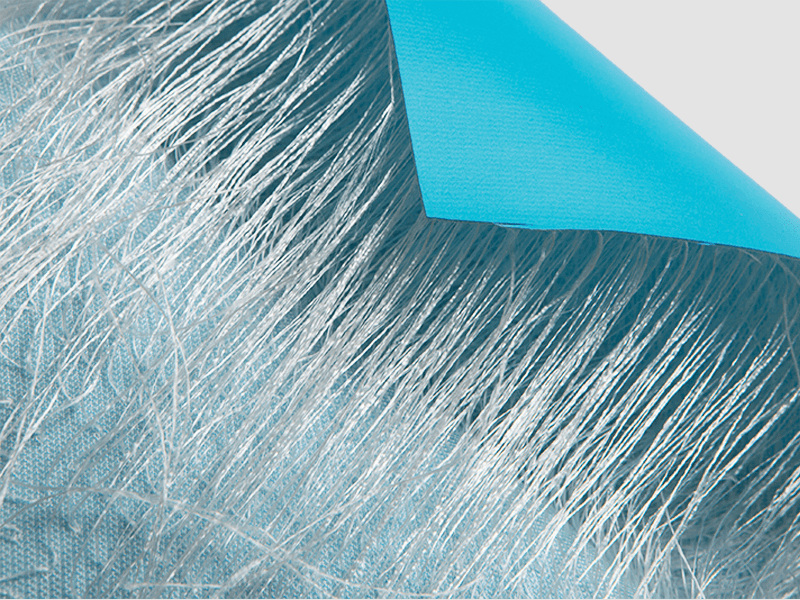

To ensure the durability of PVC inflatable fabric, the most basic requirement is to select high-quality raw materials. PVC material itself has strong tensile resistance and UV resistance, which makes the inflatable fabric less prone to aging, cracking and fading in daily use. In addition, the base material of the fabric usually uses high-strength polyester fiber (or nylon, etc.), which has strong tensile strength and flexibility.

During the production process, the uniformity of the coating and the processing technology directly affect the quality of the inflatable fabric. High-quality PVC inflatable fabric generally adopts a double-sided coating process, which can increase the strength and durability of the fabric. In addition, through hot pressing curing treatment, ensure that the PVC coating is firmly combined with the fabric base material to avoid coating shedding and fabric peeling.

The uniform distribution of PVC coating can effectively avoid uneven local force on the fabric and reduce the risk of damage.

The various parts are connected by high-frequency welding or hot pressing welding technology to ensure that the welding parts are well sealed and will not leak or break due to air pressure or friction during use.

PVC materials themselves have a certain resistance to UV rays, but high-quality PVC inflatable fabrics will have UV (ultraviolet) agents added during the production process to enhance their resistance to sunlight and heat. This can effectively prevent the fabric from brittleness, fading and loss of strength due to long-term exposure to the sun.

In addition, modern PVC inflatable fabrics have enhanced antioxidant capacity, reducing the risk of aging in extreme environments. Proper UV protection not only helps to extend the life of the fabric, but also maintains its appearance and physical properties.

The thickness of PVC inflatable fabrics is an important factor affecting its durability. Generally, thicker fabrics have higher tensile and abrasion resistance, so they can withstand greater external forces and long-term use. Depending on the use environment, manufacturers will choose PVC fabrics of different thicknesses. For example, inflatable boats, lifesaving facilities, etc. usually use thicker fabrics (0.8mm-1.0mm), while inflatable toys or decorative items may use thinner fabrics.

Quality control is another key factor to ensure the long-term durability of PVC inflatable fabrics. During the production process, manufacturers will conduct strict quality inspections on each batch of fabrics, including:

Ensure that there are no air leaks at welding points and joints.

Test the waterproof performance of the fabric when used in water to ensure that it is watertight.

Test the wear resistance of the fabric to ensure that the fabric will not be easily damaged during repeated use.

UV resistance test: Check the durability and UV resistance of the fabric in the sun.

Although PVC inflatable fabrics have high durability, their service life is still affected by the use environment and storage method:

Although PVC fabrics have UV resistance, long-term exposure to strong sunlight will accelerate the aging of the fabric. In order to extend the service life, it is recommended to place the inflatable products in a cool and dry place when not in use.

PVC inflatable fabrics should avoid contact with sharp objects during use to avoid scratches or punctures. Especially when used outdoors, care should be taken to avoid contact with objects such as stones and branches.

Keeping the fabric clean will help extend its service life. Mild soapy water should be used when cleaning, and detergents containing strong chemical ingredients should be avoided to avoid damage to the coating.

In order to maintain the good performance of PVC inflatable fabrics, it is also very important to regularly check the condition of the inflatable equipment. Check the welding seams, air valves and other interface parts to ensure that there is no damage or leakage. Any small cracks or damaged parts found should be repaired in time to prevent the problem from expanding.

The use environment of PVC inflatable fabrics also affects their durability. Generally speaking, inflatable fabrics are suitable for mild climate conditions and dry environments. In extreme temperatures (too high or too low) and humid environments, the performance of PVC fabrics may be reduced, so special attention should be paid when using them in these environments.

Correct storage and transportation methods can avoid damage to the fabric. For example, inflatable products should be deflated during storage and try to avoid heavy pressure to prevent the fabric from deformation or rupture due to squeezing. During transportation, it should also be ensured that the fabric is not exposed to sharp objects or high temperature environments.

The durability and service life of PVC inflatable fabrics are due to high-quality raw materials, advanced production processes, appropriate thickness selection and strict quality control. During use, reasonable maintenance and storage are also important factors in extending its service life. Through these measures, it can be ensured that PVC inflatable fabrics can maintain their performance for a long time and adapt to a variety of application environments.

English

English русский

русский Français

Français Español

Español