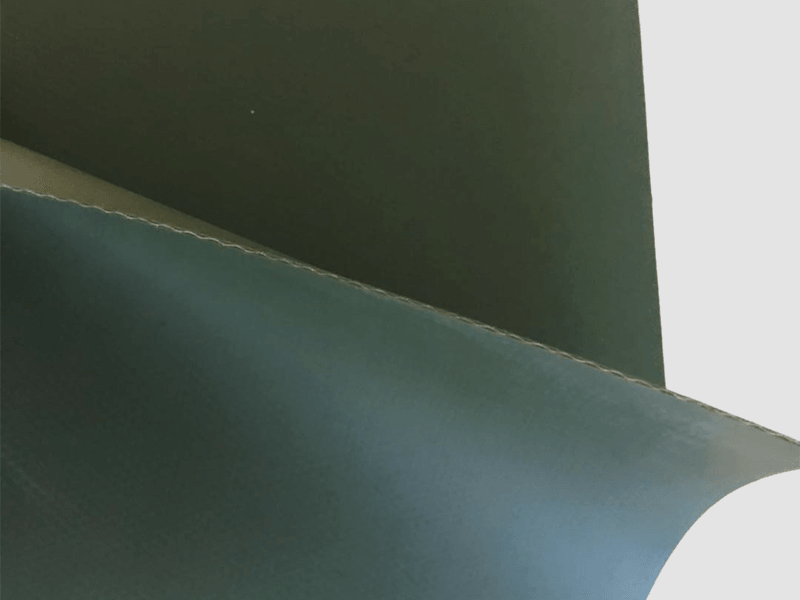

Ensuring that the TPU coating or film in TPU Fabric is evenly distributed on the substrate is a key step in the production process. Uniformity directly affects the performance of the fabric (such as waterproofness, breathability, wear resistance, etc.) and the quality of the final product. The following is a detailed analysis and solution:

1. Process selection and optimization

(1) Coating process

Scrapping method: Use a scraper to evenly coat the TPU solution on the substrate surface.

Advantages: The coating thickness can be precisely controlled.

Challenges: It is necessary to ensure that the substrate is flat and the scraper pressure is consistent, otherwise the coating thickness may be uneven.

Optimization measures: Adjust the scraper angle, speed and pressure to ensure uniform coating distribution.

Spraying method: Use a spray gun to atomize the TPU solution and spray it onto the substrate.

Advantages: Suitable for substrates with complex shapes.

Challenges: Local accumulation or leakage may occur during the spraying process.

Optimization measures: Control the spraying distance, speed and nozzle uniformity to ensure complete coverage.

Dipping method: Dip the substrate into the TPU solution, then take it out and cure it.

Advantages: Simple operation, suitable for large-scale production.

Challenges: Dipping time, speed and solution concentration may affect the uniformity of the coating.

Optimization measures: Accurately control the dipping time and solution viscosity to avoid being too thick or too thin.

(2) Lamination process

Hot melt lamination: Heat the TPU film and press it with the substrate.

Advantages: The thickness of the TPU film is controllable, suitable for high-performance applications.

Challenges: Uneven distribution of temperature and pressure may cause poor bonding or bubbles.

Optimization measures: Use precision hot pressing equipment to ensure uniform distribution of temperature and pressure.

Adhesive lamination: Use adhesive to bond the TPU film to the substrate.

Advantages: High flexibility, suitable for substrates of various materials.

Challenges: Uneven distribution of adhesive may cause peeling or wrinkling.

Optimization measures: Use automated glue coating equipment to ensure consistent adhesive thickness.

2. Material properties and pretreatment

(1) Rheological properties of TPU materials

The rheological properties of TPU solutions or melts (such as viscosity and fluidity) are crucial to coating uniformity.

Optimization measures: Adjust TPU molecular weight, solvent ratio and temperature to ensure that the material has good fluidity during processing.

(2) Surface treatment of substrates

The roughness, cleanliness and hydrophilicity of the substrate surface will affect the adhesion and distribution of TPU.

Optimization measures:

Pretreat the substrate (such as grinding, cleaning or corona treatment) to improve its surface energy.

Ensure that the substrate is dry and oil-free to avoid affecting the bonding effect.

3. Equipment accuracy and control

(1) Automated equipment

The use of high-precision automated equipment can significantly improve the uniformity of coating or lamination.

Optimization measures:

Use equipment with real-time monitoring function to automatically adjust coating thickness or lamination parameters.

Use sensors to detect coating thickness and distribution and correct deviations in time.

(2) Temperature control and pressure control

During hot melt lamination or hot press molding, the uniformity of temperature and pressure is crucial.

Optimization measures:

Use a multi-zone temperature control system to ensure consistent heating plate temperature.

Use flexible rollers during lamination to adapt to minor surface irregularities on the substrate.

4. Optimization of process parameters

(1) Coating thickness

Coating thickness needs to be optimized based on specific application requirements.

Optimization measures:

Determine the optimal coating thickness range based on target performance (e.g., waterproofness, breathability).

Measure coating thickness regularly during production to ensure consistency.

(2) Curing conditions

The curing conditions (e.g., temperature, time) of TPU coatings or films have an important impact on uniformity.

Optimization measures:

Ensure uniform temperature distribution in the curing oven.

Avoid curing time that is too long or too short to prevent cracking or incomplete curing of the coating.

5. Quality control and testing

(1) Real-time monitoring

Use online detection technology (e.g., laser thickness gauge, visual inspection system) to monitor coating uniformity in real time during production.

Optimization measures:

Set alarm thresholds to automatically stop and check when thickness deviation exceeds the set range.

(2) Performance testing

Performance testing of TPU Fabric after production to verify its uniformity and functionality.

Test items:

Thickness test: Use a micrometer or multi-point thickness gauge to detect the thickness of different areas.

Waterproofness test: Evaluate the uniformity and sealing of the coating through a water pressure test.

Breathability test: Verify whether the coating affects the breathability of the substrate.

6. Actual cases and solutions

(1) Outdoor clothing

In outdoor clothing, TPU coating needs to be both waterproof and breathable. If the coating is uneven, it may cause waterproof failure or reduced breathability in certain areas.

Solution: Use high-precision scraping equipment and combine it with online thickness monitoring technology.

(2) Medical protective clothing

Medical protective clothing requires TPU coating to have high uniformity to ensure non-permeability. If the coating has pinholes or uneven thickness, it may cause liquid or virus penetration.

Solution: Strictly pre-treat the substrate before lamination and use high-precision hot-melt lamination equipment.

(3) Automotive interiors

TPU fabrics in automotive interiors need to be heat-resistant, wear-resistant and have a consistent appearance. If the coating is uneven, it may affect the touch and durability.

Solution: Use automated glue coating equipment combined with a multi-zone temperature control system.

Ensuring that TPU Fabric is evenly distributed on the substrate requires multiple aspects, including process selection, material properties, equipment accuracy, process parameter optimization, and quality control. Through scientific process design and strict production management, the problem of uneven coating or film can be effectively solved, thereby improving the performance and reliability of TPU fabrics.

Recommended Products

English

English русский

русский Français

Français Español

Español