To improve the surface flatness and inkjet adhesion of PVC Flex Banner , we can start from material selection, production process optimization and surface treatment technology. The following are specific methods and solutions for this problem:

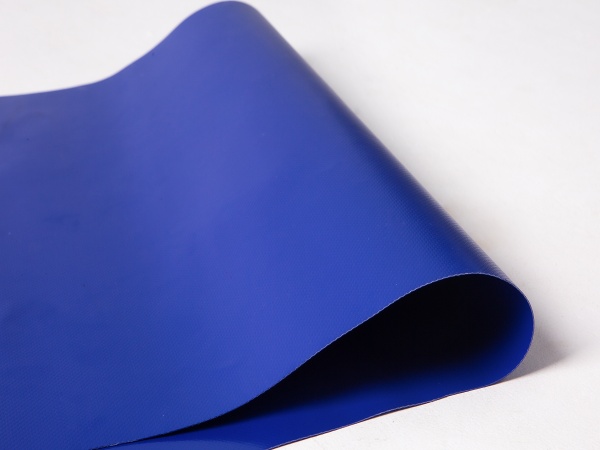

Adding an appropriate amount of additives, such as leveling agents and plasticizers, to the PVC coating material can improve the fluidity of the material and the uniformity of the coating, thereby improving the surface flatness.

Adding a binder (such as polyurethane or acrylic resin) that is highly compatible with inkjet inks to the coating increases the adhesion of the coating to the ink.

Choosing fillers with smaller particle size and more uniform distribution (such as nano-scale calcium carbonate or silica powder) to improve the fineness and surface smoothness of the coating.

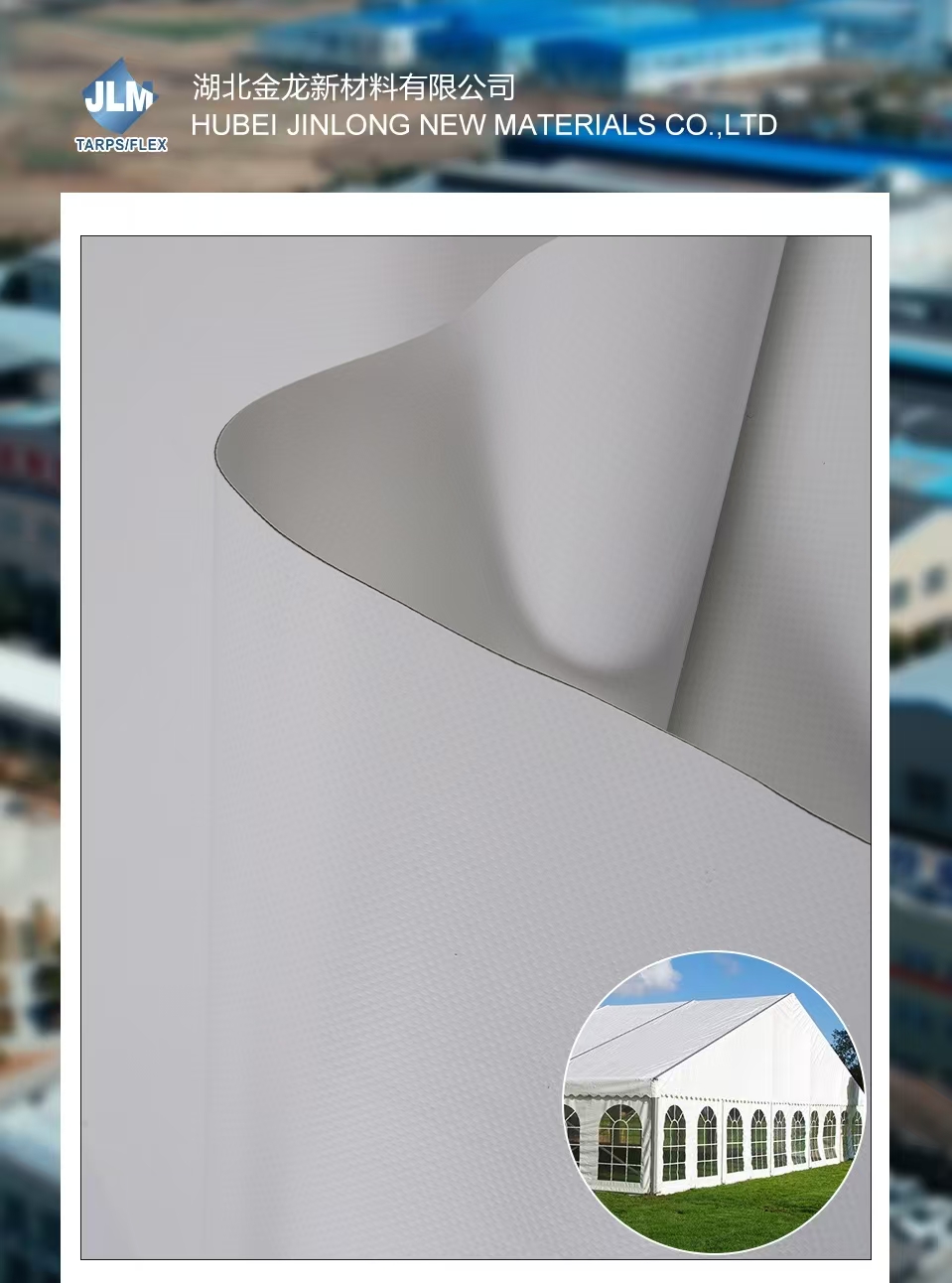

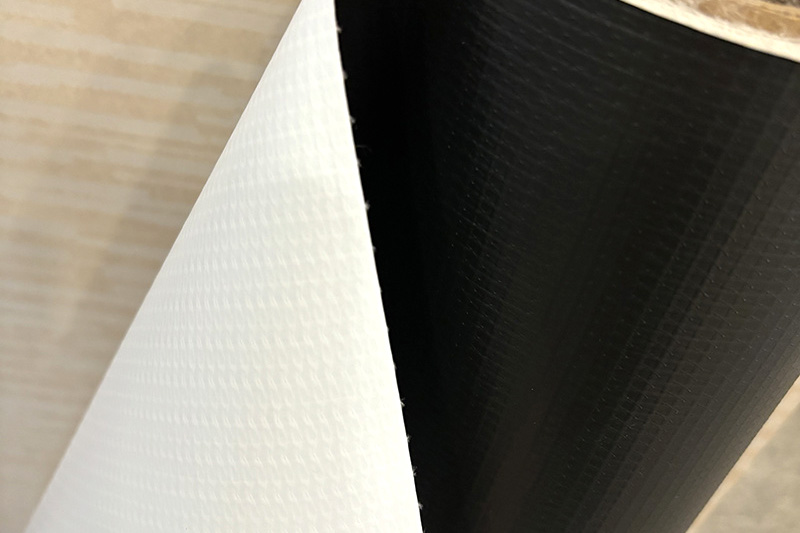

Using a fiber fabric base cloth with a higher warp and weft density can reduce surface ripples and depressions.

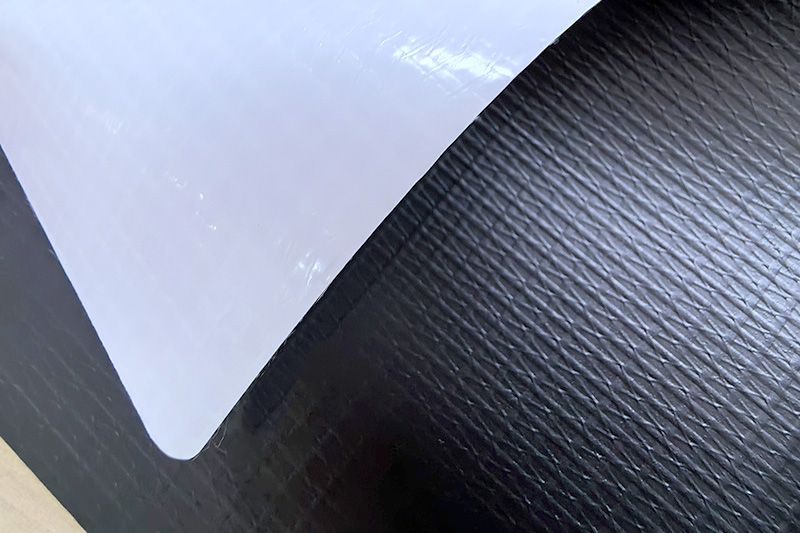

Corona treatment, plasma treatment or sandblasting of the base cloth can improve the bonding between the coating and the base cloth, and indirectly improve the uniformity and stability of the surface.

Using multiple coating processes to form a more uniform multi-layer coating structure on the surface of the inkjet cloth helps to improve the surface flatness.

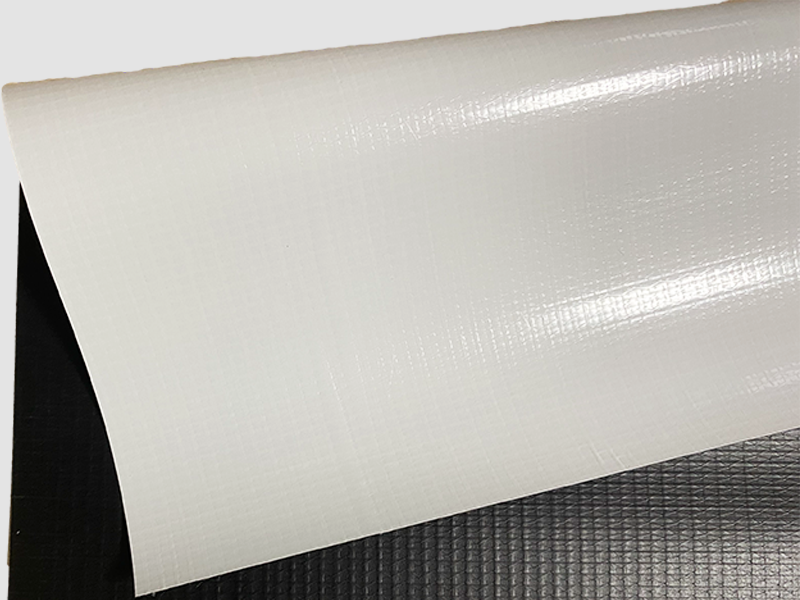

Use precision coaters (such as blade coating or gravure roller coating) to ensure consistent coating thickness.

Optimize the heating and cooling speed of the coating in the production line to avoid wrinkling or uneven surface due to thermal expansion and contraction.

Add vacuum exhaust devices to the coating production to reduce the impact of residual bubbles on flatness.

Optimize the production environment and use dust-free workshops and air filtration equipment to prevent dust particles from adhering to the coating surface.

Use corona treatment technology to improve the polarity of the PVC surface and make it more bonded with the ink.

Use plasma technology to change the molecular structure of PVC to improve the wettability and ink adhesion of the surface.

Add silicone or polyvinyl fluoride additives to the coating material to further improve the surface finish and anti-adhesion effect.

Use transparent protective coatings or sealing layers to enhance the friction resistance and anti-pollution of the coating while improving adhesion.

By spraying nano-level functional coatings (such as hydrophobic coatings), it can not only enhance the adhesion of the spray painting, but also prevent the adhesion of pollutants.

Introduce online optical flatness detection equipment during the production process to monitor the coating thickness and surface smoothness in real time to ensure consistency.

Regularly test the ink adhesion of the printed cloth with an adhesion tester (such as the 3M tape test method) to verify the effect of production process and material improvement.

To fundamentally improve the surface flatness and printing adhesion of PVC Flex Banner, it is necessary to take a three-pronged approach from the selection of raw materials, optimization of production processes, and application of surface treatment technology. At the same time, continuous optimization of the process combined with real-time detection and user feedback can maximize product performance and meet market demand.

English

English русский

русский Français

Français Español

Español