Improving the wear resistance and aging resistance of PVC Layflat Hose is the key to extending its service life and improving performance. Because PVC folding hoses are widely used in agricultural irrigation, construction site drainage, industrial transportation and other fields, they often need to withstand high mechanical wear and the impact of the external environment. Therefore, it is crucial to improve its wear resistance and aging resistance during the design and production process.

The formula of PVC material is the basis for determining the wear resistance and aging resistance of the hose. By adding different additives to PVC formulations, its properties can be significantly improved.

Oxidation is one of the main causes of aging of PVC materials. Adding antioxidants (such as vulcanizing agents, phenolic antioxidants, etc.) can effectively delay the aging process of PVC and reduce the damage to materials by ultraviolet rays and oxygen.

PVC materials are susceptible to ultraviolet (UV) rays when exposed to sunlight, causing embrittlement, discoloration and cracks on their surfaces. Adding UV absorbers (such as diphenylmethane compounds, benzotriazole compounds, etc.) can improve the UV resistance of the material and extend the service life of the hose.

The wear resistance of PVC can be improved by adding reinforcing fillers (such as calcium carbonate, silica, etc.) and wear-resistant agents (such as bauxite powder, wear-resistant coating). These fillers can enhance the surface hardness of the hose and reduce wear caused by friction.

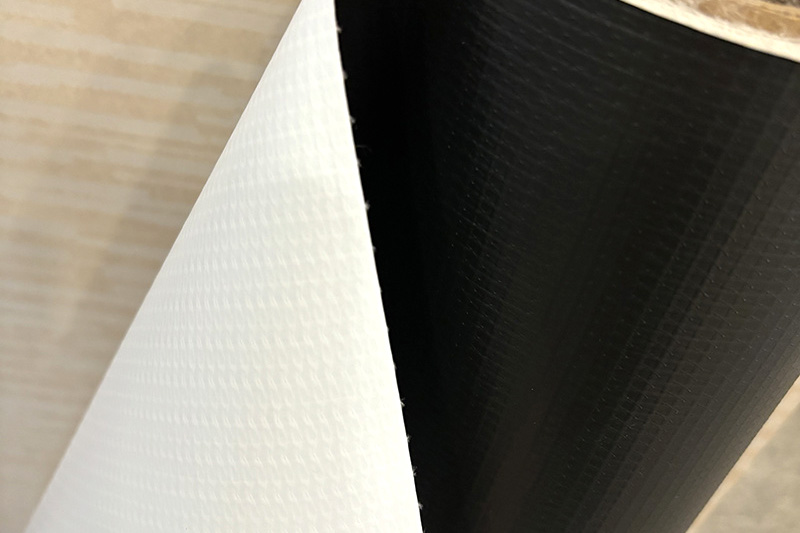

Surface treatment and coating technology are effective means to improve the wear resistance and aging resistance of PVC folding hoses.

Applying a special wear-resistant layer and anti-corrosion coating on the inner and outer surfaces of PVC folding hoses can effectively reduce damage caused by friction and chemical corrosion during long-term use of the hose. For example, using wear-resistant polyurethane coating or acrylic coating can greatly improve the wear resistance of the hose surface.

Through processes such as chemical hardening and heat treatment, a hardened layer is formed on the surface of PVC hoses, which can enhance its wear resistance. For example, laser surface treatment or hot air treatment can form a harder coating on the surface and improve wear resistance.

Anti-aging agents play an important role in the antioxidant, UV resistance, high temperature resistance and other properties of PVC hoses. By adding different types of anti-aging agents to the PVC formula, its aging resistance can be significantly improved.

PVC is prone to thermal degradation in high-temperature environments. Adding thermal stabilizers (such as calcium and zinc compounds) can improve the material's high-temperature resistance and prevent the hose from embrittlement or melting in high-temperature environments.

Prolonged exposure to UV rays will accelerate the aging of PVC materials. By adding light stabilizers, the resistance of the hose to ultraviolet rays can be effectively improved and surface aging can be delayed, making it especially suitable for outdoor use.

Plasticizers can enhance the flexibility of PVC and reduce the risk of hardening or brittleness during aging. However, you need to be cautious when selecting plasticizers. Some plasticizers may cause the aging of PVC materials to accelerate during long-term use. It is necessary to choose stable and environmentally friendly plasticizers.

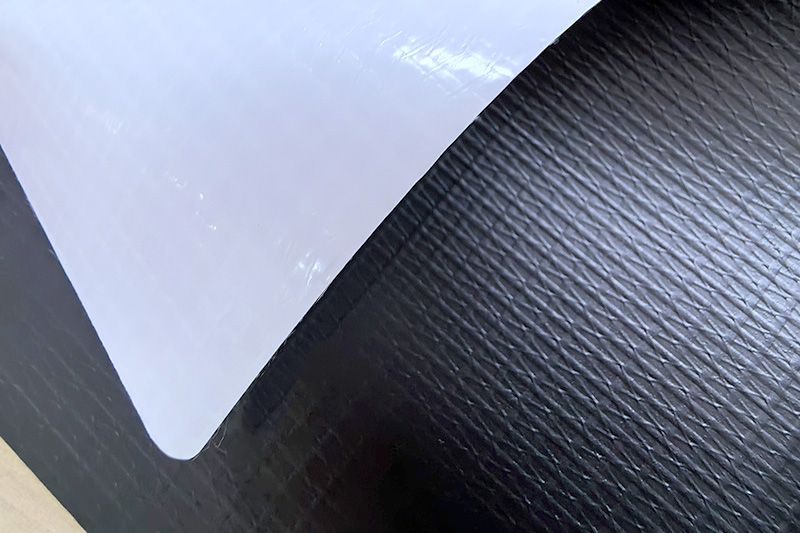

By adding reinforcing materials, such as fiber braiding, steel mesh, etc., to PVC folding hoses, its wear resistance and aging resistance can be improved.

Adding polyester fiber braiding layer to PVC hose can significantly improve the tensile strength and wear resistance of the hose. The fiber braid not only improves the wear resistance of the hose, but also enhances its structural stability during long-term use and prevents external mechanical wear and stretching.

For environments that need to withstand high pressure and load, adding a steel mesh reinforcement layer can improve the pressure resistance and wear resistance of the hose. The addition of steel wire mesh can not only improve the strength of the hose, but also improve the anti-aging performance and prevent the hose from breaking or deforming during long-term use.

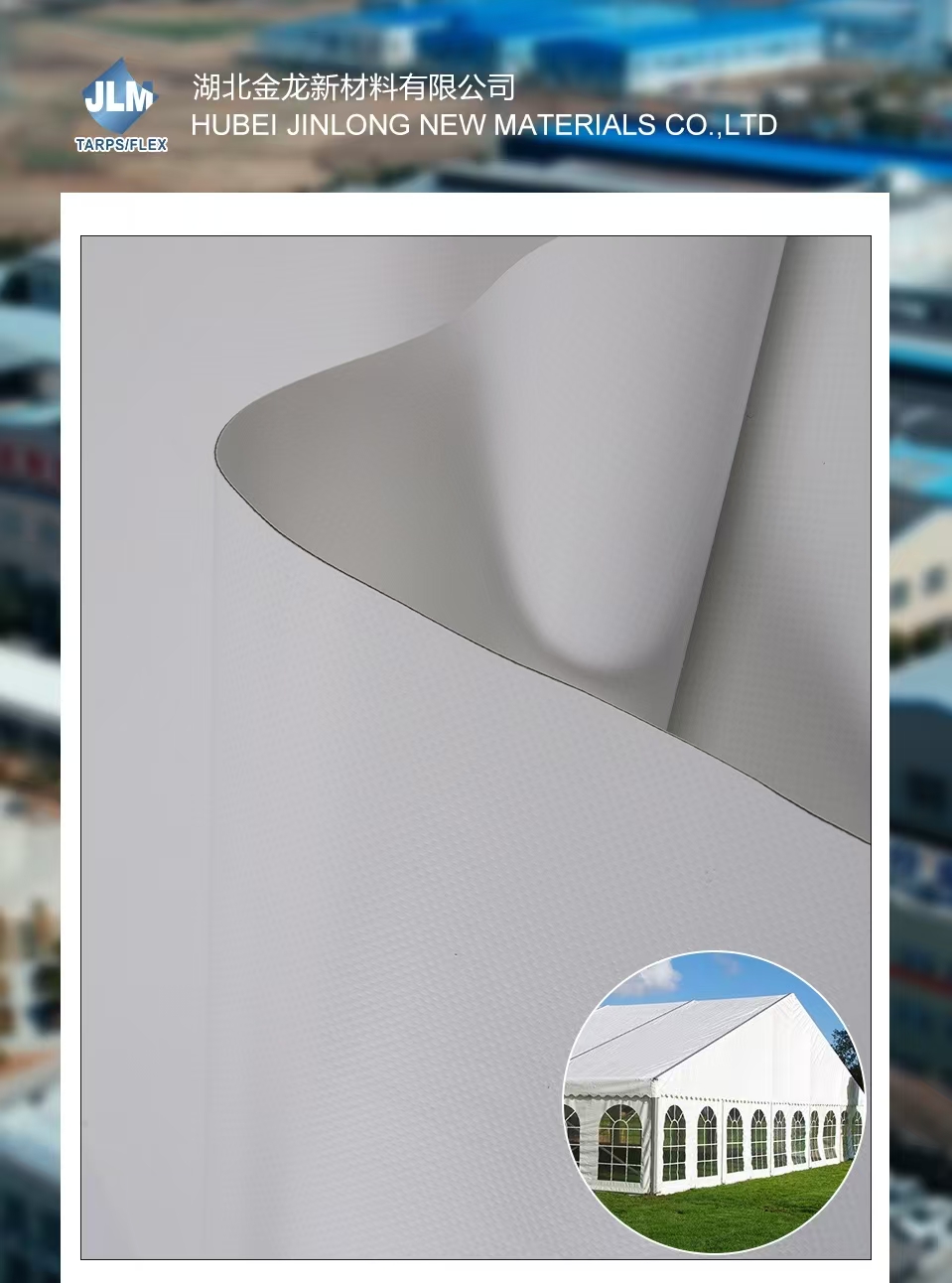

The thickness and structural design of PVC folding hose directly affect its wear resistance and aging resistance.

The wall thickness of a hose is closely related to its wear resistance and aging resistance. Thicker wall thickness provides better protection from excessive wear. In addition, the wall thickness design should be optimized according to the usage environment of the hose to avoid being too thick, resulting in insufficient flexibility, or being too thin, resulting in poor durability.

During the design process of the hose, rationally equipping it with different reinforcement layers and internal and external coatings can improve its overall performance. For example, adding an anti-corrosion coating to the inner layer and a wear-resistant coating to the outer layer can extend the service life of the hose in complex environments.

The production process of PVC folding hose has an important impact on its wear resistance and aging resistance. During the production process, factors such as extrusion temperature, cooling rate, and pressure control will affect the molecular structure of the material, thereby affecting the overall performance of the hose.

Proper temperature and cooling rate help optimize the molecular arrangement of PVC and improve its mechanical properties and wear resistance. During the production process, temperatures that are too high or too low may cause a loss of material properties and affect the durability of the hose.

During the extrusion process, appropriate pressure can help PVC molecules bind tightly, increase the density and hardness of the material, and thereby enhance its wear resistance. Too low pressure may cause the material to be uneven, and too high pressure may cause excessive deformation or aging of the material.

These measures can not only extend the service life of the hose, but also provide stable and efficient fluid delivery in various complex environments.

English

English русский

русский Français

Français Español

Español