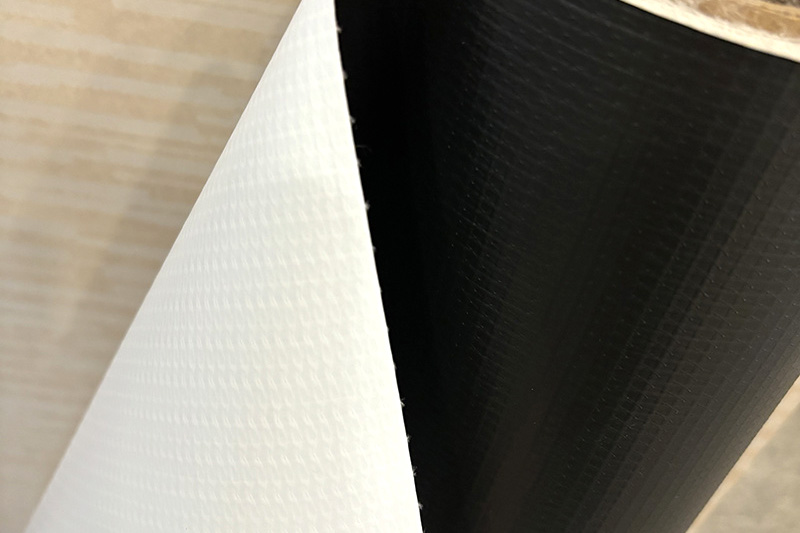

TPU fabric is generally easier to process and shape at high temperatures. As a thermoplastic material, TPU can be molded when heated and retains its shape upon cooling. Environmental temperature is a critical factor during processing.

Certainly, there are specific processing temperature ranges. The molding temperature for TPU typically ranges from 170°C to 230°C, with the exact temperature determined by factors such as the specific grade of TPU, pellet size, equipment capabilities, and production speed. Within this temperature range, TPU exhibits good flowability and malleability, facilitating a smoother processing experience.

In addition to temperature, other process requirements must be considered when processing TPU. For instance, during injection molding, factors such as injection pressure, injection speed, and mold temperature all affect the quality of the final product. In extrusion molding, parameters like screw speed, back pressure, and traction speed need to be carefully adjusted and confirmed.

To ensure the processing quality and performance of TPU fabric, it is necessary to conduct thorough experiments and tests before processing to determine the optimal process parameters. Similarly, strict quality control measures are required during the processing to ensure that each batch of products meets the expected performance requirements.

In summary, TPU fabric is relatively easy to process at high temperatures, but it is essential to control the processing temperature and adhere to basic process specifications to ensure the quality of the finished product.

English

English русский

русский Français

Français Español

Español