1. Custom Fabrication: Tailoring PVC tarpaulin products to meet the exact specifications of an industrial application can significantly enhance their effectiveness. Custom sizes, shapes, and reinforcement at critical points can ensure that the tarpaulin perfectly fits the intended use, whether for covering machinery, creating barriers, or protecting goods during transportation.

2. Enhanced Durability Treatments: Applying treatments to improve the UV resistance, anti-microbial properties, and flame retardancy of PVC tarpaulins can extend their lifespan and functionality in harsh industrial environments. Such treatments can make PVC tarps more suitable for long-term outdoor use, in chemically aggressive environments, or in settings where fire safety is a concern.

3. Integration with Industrial Systems: Designing PVC tarpaulins that can be easily integrated with existing industrial systems, such as automated cover systems, can enhance efficiency and safety. For example, tarps that are compatible with mechanical rolling and unrolling systems can reduce the need for manual labor and minimize the risk of injuries.

4. Recycling and Repurposing: Implementing recycling programs for PVC tarpaulin can help industries minimize waste and adhere to sustainability goals. Encouraging the repurposing of old or damaged tarps for different applications within the industry can also contribute to environmental efforts and cost savings.

5. Technological Innovations: Incorporating new technologies, such as smart sensors or RFID tags, into PVC tarpaulins can open up possibilities for tracking goods in transit, monitoring the condition of covered items, or even assessing the health of the tarpaulin itself. This can lead to improved logistics, maintenance, and asset management.

6. Employee Training: Educating employees on the proper handling, maintenance, and potential applications of PVC tarpaulins can maximize their utility and lifespan. Training can cover topics such as correct folding and storage techniques, cleaning procedures, and safety practices when installing or removing large tarps.

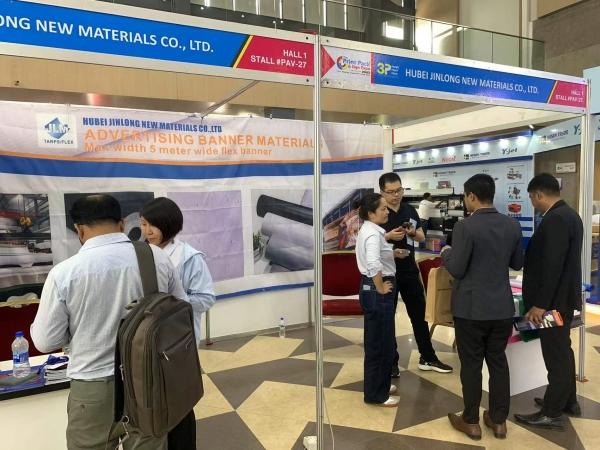

7. Collaboration with Manufacturers: Working closely with PVC tarpaulin manufacturers can lead to the development of innovative solutions tailored to specific industrial challenges. Collaboration can also facilitate feedback loops for continuous improvement of tarpaulin products based on real-world usage and performance data.

8. Regulatory Compliance: Ensuring that PVC tarpaulin products comply with industry-specific regulations and standards can prevent legal issues and promote workplace safety. This includes compliance with fire safety standards, environmental regulations, and material handling guidelines.

By adopting these strategies, industries can enhance the efficiency, safety, and sustainability of their operations using PVC tarpaulin. This versatile material offers a range of benefits that, when fully utilized, can contribute significantly to the success of industrial applications.

English

English русский

русский Français

Français Español

Español