Lumber tarps are, by far, the popular flatbed truck tarps and truckers and haulers, keeping your load protected and trusting your lumber will arrive at its destination undamaged. Lumber tarps are suited for long, tall loads such as stacked wood, wallboard, and other products that can be damaged by rain, UV rays, or road debris.

Lumber tarps are designed with a flap at the end to cover the ends of lumber on a flatbed truck. Detailed craftsmanship ensures that these sturdy tarps stand up to the elements, punctures, wear, and tear, and tough environments. Whether it is lumber, refuge, steel, heavy equipment, or temperature-sensitive asphalt. These are made with versatile, strong, and easy-to-handle materials including 18-ounce vinyl-coated fabric available in standard and custom sizes for any trucking requirement including flatbeds, coil trailers, transfer trailers, dump trucks, and roll-offs. The heat-sealed vinyl seams and double lock-stitched hems deliver sturdiness, versatility, and resilience. The sides and flap are fitted with three rows of D-rings to make fast and secure connections using rubber tarp straps, rubber rope, and s-hooks. Each D-ring has an abrasion-resistant pad underneath to protect the tarp and keep it in working condition.

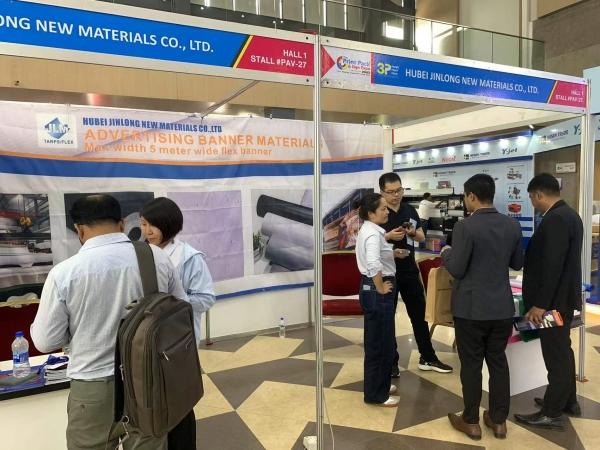

The raw material of lumber tarp is PVC tarpaulin. High-tenacity Industries yarn coated with PVC Resin to reach various colors, embossed patterns, and prints. Various Additives case different tarpaulin materials to meet specific industry applications.

Below are the basic features of tarpaulin:

1) High tensile strength and adhesion

2) Fire retardant; tear-resistant

3) Anti-fungus treatment

4) Anti-abrasive property

5) UV treated

6) Water-sealed and airtight

7) Antifreeze and corrosion-resistant

Below is the basic usage for tarpaulin:

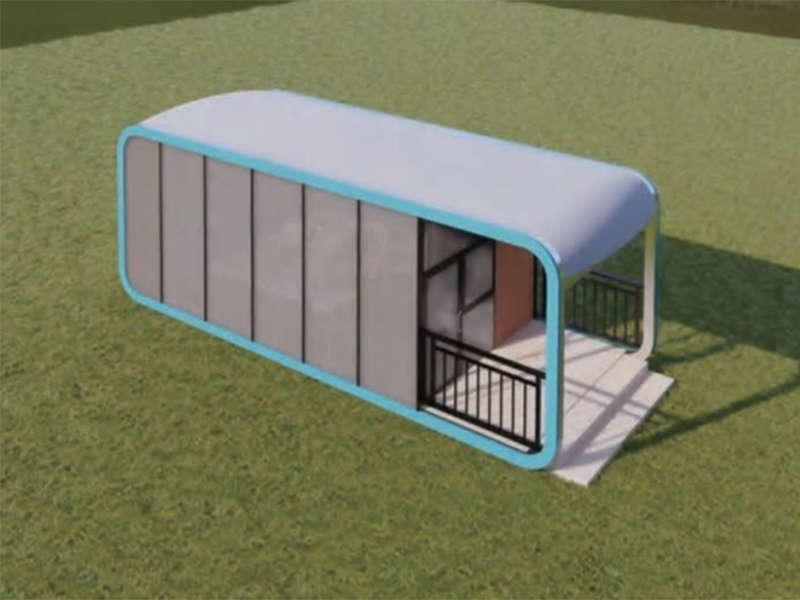

1) Make a sunshade and protection awning

2) Truck tarpaulin, side curtain, and train tarpaulin

3) Building and stadium top cover material

4) Make lining and cover of camping tents

5) Make swimming pool, airbed, inflate boats

English

English русский

русский Français

Français Español

Español