Early Uses and Simple Covers

Initially, tarpaulins were made from canvas or other types of cloth, treated with oils or waxes to render them waterproof. These early tarps were primarily used for covering goods on ships, protecting them from sea spray and rain. With the advent of PVC in the early 20th century, manufacturers began to explore its potential in various applications, including tarpaulin production.

PVC tarpaulin emerged as a superior alternative to traditional materials due to its inherent water resistance, durability, and ease of maintenance. Early PVC tarps were simple in design and function, mainly serving as covers for trucks, boats, and industrial goods to protect them from the elements.

Technological Advancements and Material Improvements

Over time, advancements in polymer chemistry and manufacturing processes led to significant improvements in PVC tarpaulin's physical properties. These enhancements included increased tear resistance, UV protection, and flexibility in extreme temperatures. Such improvements expanded the material's applicability beyond simple covers to more demanding protective roles.

Diversification into Various Industries

As the material properties of PVC tarpaulin improved, its uses diversified into several industries. In construction, it became essential for scaffolding covers, ground sheets, and temporary shelters, offering protection against weather and debris. The agriculture sector adopted PVC tarps for grain storage, livestock sheltering, and greenhouse covers, benefiting from its durability and weather resistance.

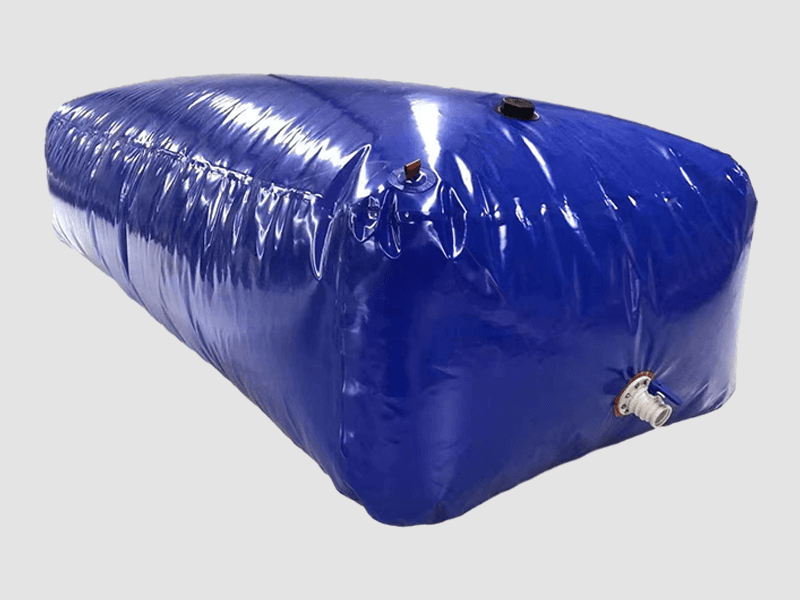

The material's strength and resistance to chemicals also made it suitable for industrial and environmental applications, such as containment liners for hazardous materials and erosion control products. Furthermore, its ability to be easily cleaned and sanitized led to its use in humanitarian efforts, providing temporary housing and emergency shelters in disaster-stricken areas.

Innovation in Recreational and Consumer Goods

Innovation in PVC tarpaulin manufacturing expanded its use into recreational and consumer goods. Products such as inflatable boats, water slides, and outdoor gear began to utilize PVC tarps for their waterproof and durable qualities. The material's versatility also allowed for its use in making bags, protective clothing, and various custom applications, catering to specific consumer needs.

The Future: Sustainability and New Technologies

The evolution of PVC tarpaulin continues as manufacturers focus on sustainability and environmental responsibility. Advances in recycling processes and the development of eco-friendly additives are making PVC tarps more sustainable. Additionally, ongoing research into new formulations and technologies promises to further expand the applications of PVC tarpaulin, potentially leading to even more innovative uses in the future.

From simple covers to a critical component in complex applications across diverse sectors, PVC tarpaulin has evolved significantly. Its journey reflects the broader trends in material science and technology, demonstrating how innovation can transform a basic material into a multifaceted solution for modern challenges.

English

English русский

русский Français

Français Español

Español