How does the PVC lamination contribute to the tarpaulin's durability and strength?

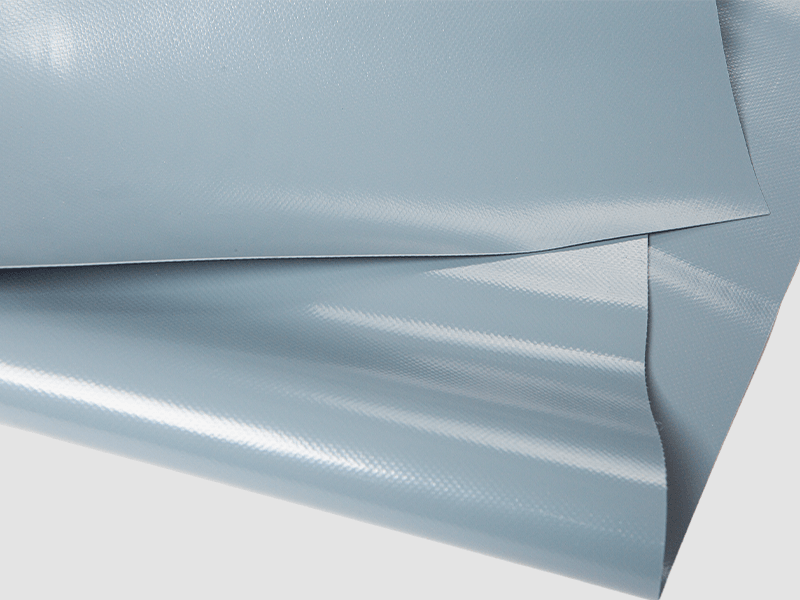

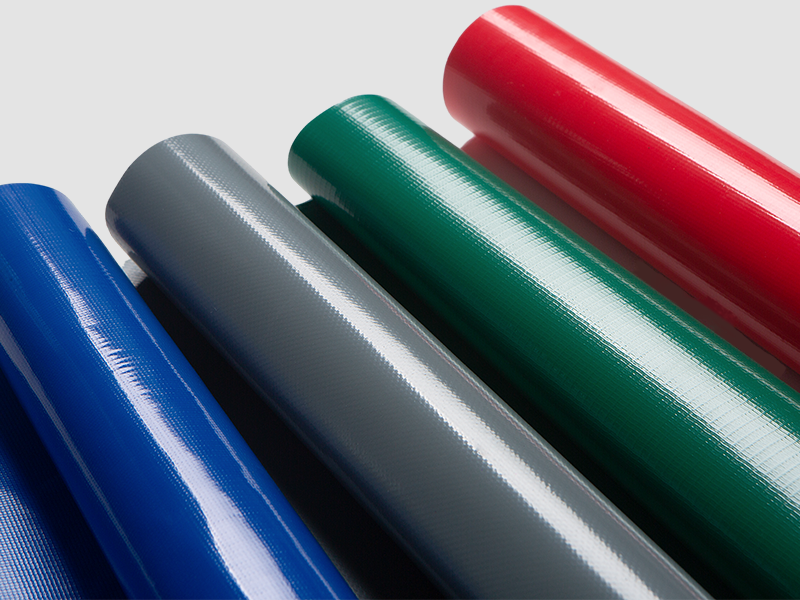

Enhanced Weather Resistance: PVC lamination provides a protective barrier against environmental elements such as UV radiation, moisture, and temperature variations. This prevents degradation of the fabric and ensures that the tarpaulin remains resilient to prolonged exposure to sunlight, rain, snow, and other weather conditions.

Waterproofing: The PVC layer effectively seals the fabric, making the tarpaulin waterproof. This prevents water from penetrating the material, keeping the covered items dry and protected from moisture-related damage. It's particularly crucial for outdoor applications where items need to be shielded from rain, snow, or humidity.

Increased Tensile Strength: The PVC layer adds strength and stability to the fabric, enhancing its tensile strength. This makes the tarpaulin more resistant to tearing, stretching, and other mechanical stresses, ensuring that it can withstand the rigors of handling, installation, and use without compromising its integrity.

Abrasion Resistance: PVC lamination provides an extra layer of protection against abrasion and wear. This is especially beneficial for tarpaulins used in rugged environments or applications where they may come into contact with rough surfaces or sharp objects. The PVC coating helps prolong the lifespan of the tarpaulin by reducing damage from friction and impact.

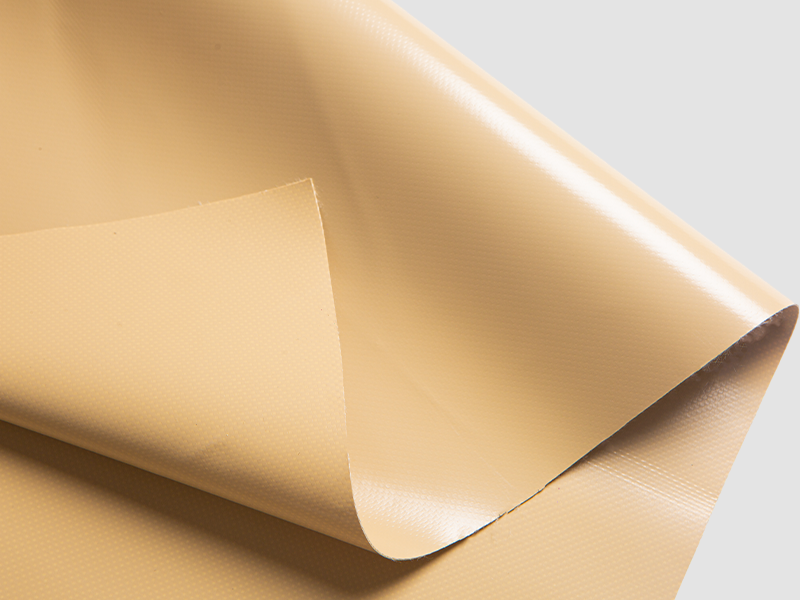

Flexibility and Flex Crack Resistance: Despite adding strength, PVC lamination maintains the flexibility of the fabric, allowing it to conform to various shapes and contours. This flexibility is essential for easy handling, folding, and storage of the tarpaulin. Additionally, PVC lamination helps prevent the formation of cracks or fractures in the fabric, even when subjected to repeated bending or folding, ensuring long-term durability and performance.

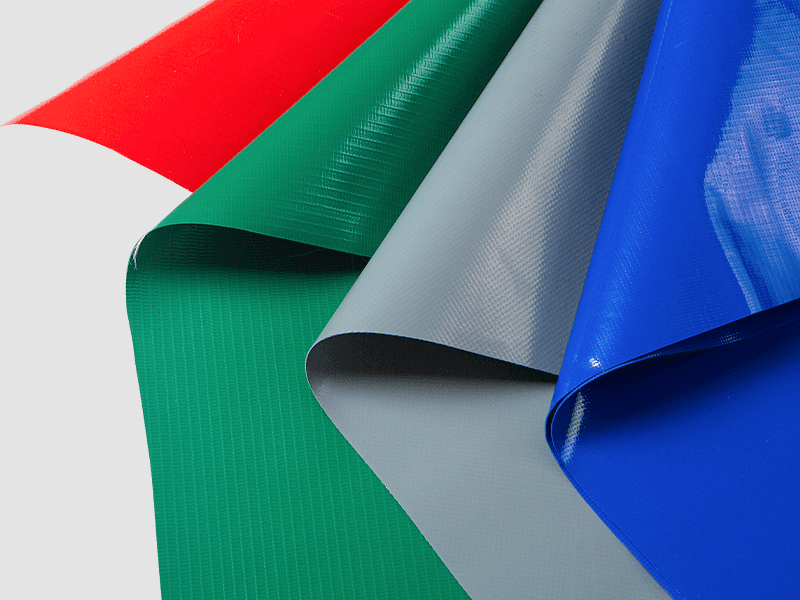

PVC lamination significantly enhances the durability and strength of tarpaulin, making it suitable for a wide range of applications, including construction, agriculture, transportation, and outdoor storage. It provides protection against weather damage, improves mechanical properties, and prolongs the lifespan of the tarpaulin, ensuring reliable performance and value for users.

Are there specific reinforcement techniques or features available to enhance the tarpaulin's performance in high-stress areas or applications?

There are several specific reinforcement techniques and features available to enhance the performance of

PVC laminated tarpaulin in high-stress areas or applications. These reinforcements help to strengthen the tarpaulin and prolong its lifespan, especially in areas where it experiences increased tension, abrasion, or wear. Some common reinforcement techniques and features include:

Reinforced Edges: Reinforced edges are achieved by folding over and heat-sealing or stitching the edges of the tarpaulin fabric, often with additional layers of PVC material or webbing. This reinforcement helps prevent fraying and tearing along the edges, which are typically more susceptible to damage during handling and installation.

Double-Stitched Seams: Double-stitched seams involve sewing two lines of stitching parallel to each other along the edges or seams of the tarpaulin. This provides extra strength and durability to the seams, reducing the risk of seam failure and seam separation under tension or stress.

Webbing Reinforcement: Webbing reinforcement involves attaching strips of woven polyester or nylon webbing to specific areas of the tarpaulin, such as corners, grommet holes, or load-bearing points. The webbing provides additional strength and support, distributing stress more evenly and reducing the risk of tearing or stretching in high-stress areas.

Grommets and D-Rings: Grommets and D-rings are metal or plastic hardware components that are installed along the edges or corners of the tarpaulin. These reinforcements provide attachment points for ropes, bungee cords, or tie-downs, allowing the tarpaulin to be securely fastened and tensioned without causing damage to the fabric.

Patch Kits: Patch kits contain adhesive-backed PVC patches or fabric patches that can be applied to damaged or worn areas of the tarpaulin to reinforce and repair them. These patches provide a quick and effective solution for addressing minor tears, punctures, or abrasions, extending the lifespan of the tarpaulin and preventing further damage.

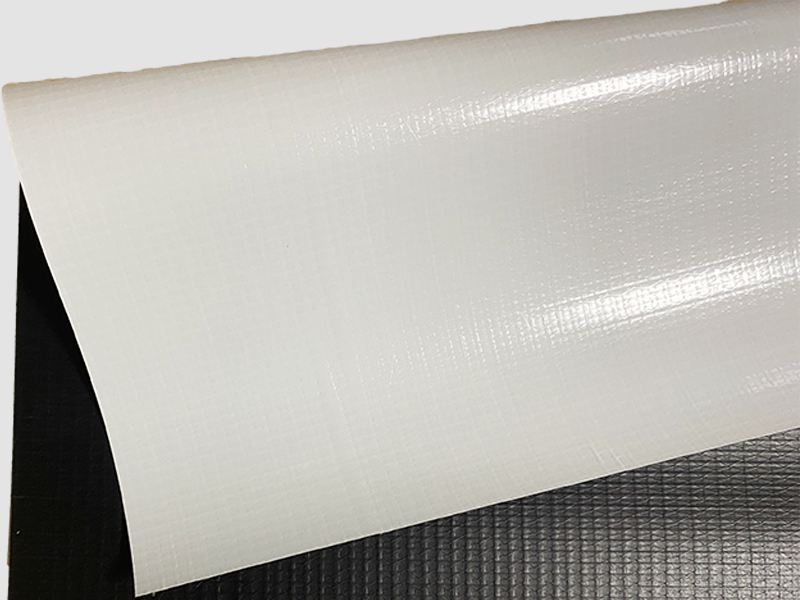

Cross-Weave Fabric: Some PVC laminated tarpaulins feature a cross-weave fabric construction, where the base fabric is woven in a crosshatch pattern for added strength and stability. This construction enhances tear resistance and tensile strength, making the tarpaulin more durable and resilient in high-stress applications.

These reinforcements help ensure that the tarpaulin can withstand the demands of high-stress areas, prolonging its lifespan and providing reliable protection for covered items.

English

English русский

русский Français

Français Español

Español