During the long-term outdoor use of PVC Tarpaulin, the problems of fading, cracking or aging are mainly due to factors such as ultraviolet radiation, temperature changes, moisture, wind and sand wear.

1. Add anti-ultraviolet (UV) stabilizers

Ultraviolet radiation is one of the main reasons for the fading and brittleness of PVC tarpaulins. By adding anti-ultraviolet agents (UV stabilizers) to PVC raw materials, its resistance to ultraviolet rays can be significantly improved, and material aging and fading caused by ultraviolet rays can be reduced. Common anti-ultraviolet additives include titanium dioxide, UV absorbers, etc. These additives can effectively block the penetration of ultraviolet rays and extend the service life of the tarpaulin.

2. Use anti-aging plasticizers

The role of plasticizers is to improve the flexibility of PVC, but some plasticizers may volatilize under high temperature or long-term exposure, resulting in material brittleness. In order to ensure the aging resistance of PVC Tarpaulin, you can choose low-volatility plasticizers or environmentally friendly plasticizers, such as phosphate plasticizers, epoxy plasticizers, etc. These plasticizers are not easy to volatilize during long-term use, which helps to maintain the flexibility and durability of the material.

3. Add antioxidants

PVC Tarpaulin is prone to oxidation when exposed to air, moisture and oxygen, causing material aging, hardening or brittle cracking. Adding antioxidants (such as phosphites, phenolic antioxidants) can effectively delay the oxidation process and enhance the aging resistance of the material.

4. Use high-temperature and low-temperature resistant material formulas

Long-term temperature changes (such as high temperatures in summer and low temperatures in winter) will cause thermal expansion and contraction of PVC materials, which may cause cracks or ruptures. Therefore, the high-temperature and low-temperature resistance of PVC can be improved by optimizing the formula of PVC, selecting materials with higher thermal stability, and adding thermal stabilizers to ensure that it remains flexible and crack-resistant at extreme temperatures.

5. Coating and surface protection

In order to enhance the weather resistance of PVC Tarpaulin, many products are coated with a protective coating. These coatings not only enhance waterproofness, but also improve UV resistance and chemical corrosion resistance. Commonly used coatings include polyurethane coatings, fluorocarbon coatings, etc. These coatings can effectively isolate the external environment and reduce the damage of ultraviolet rays, wind and sand, and moisture to the material.

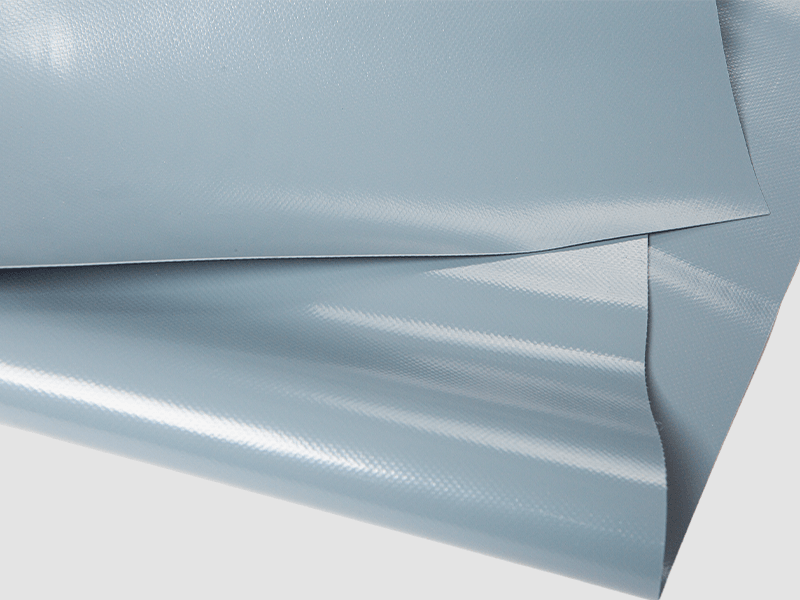

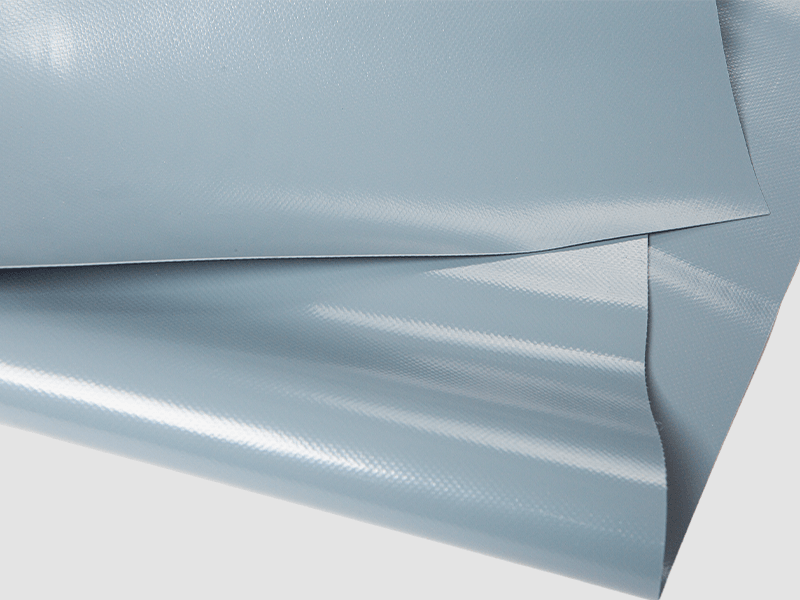

6. Use double-layer structure or composite materials

Use double-layer structure or composite materials to enhance the strength and durability of PVC Tarpaulin. For example, polyester fiber or other reinforcing materials can be added between the PVC layer and the inner fabric, which can not only improve the tensile strength of the PVC tarpaulin, but also reduce the material degradation caused by ultraviolet radiation.

7. Choose high-quality PVC raw materials

The quality of PVC directly affects its anti-aging ability. High-quality PVC raw materials usually contain fewer impurities and impurities, and their molecular structure is more stable. Selecting PVC raw materials that have been strictly screened and meet international standards can effectively improve its UV resistance and weather resistance.

8. Regular maintenance and cleaning

After long-term outdoor use, PVC Tarpaulin may accumulate dust, stains, grease, etc. These substances not only affect the appearance, but may also accelerate its aging process. Clean and maintain the tarpaulin regularly to avoid material damage caused by long-term accumulation of impurities. When cleaning, use a mild detergent and avoid using chemicals containing strong acids or strong alkalis, which may damage the protective layer on the PVC surface.

9. Proper storage and use

Storage conditions are crucial to the long-term performance of PVC Tarpaulin. Avoid exposing it to sunlight or high temperatures for a long time, especially when not in use. When storing, try to place it in a dry, cool place to avoid direct contact with moisture and ultraviolet rays. If the PVC tarpaulin needs to be rolled up for storage, make sure it is free of water or moisture to avoid mold or other corrosion problems.

10. Enhanced resistance to wind and sand wear

In some windy and sandy environments, the surface of PVC Tarpaulin may be worn due to friction with sand particles. In order to improve its resistance to wind and sand wear, anti-wear additives can be added during the production process or high-strength fabrics can be selected to enable it to maintain good performance in harsh environments.

To ensure that PVC Tarpaulin does not fade, crack or age during long-term outdoor use, the key is to select the right raw material formula, additives and protective coating, combined with reasonable storage management and regular maintenance. By taking the above measures, its service life can be significantly extended and its stability and reliability in harsh environments can be improved.

English

English русский

русский Français

Français Español

Español