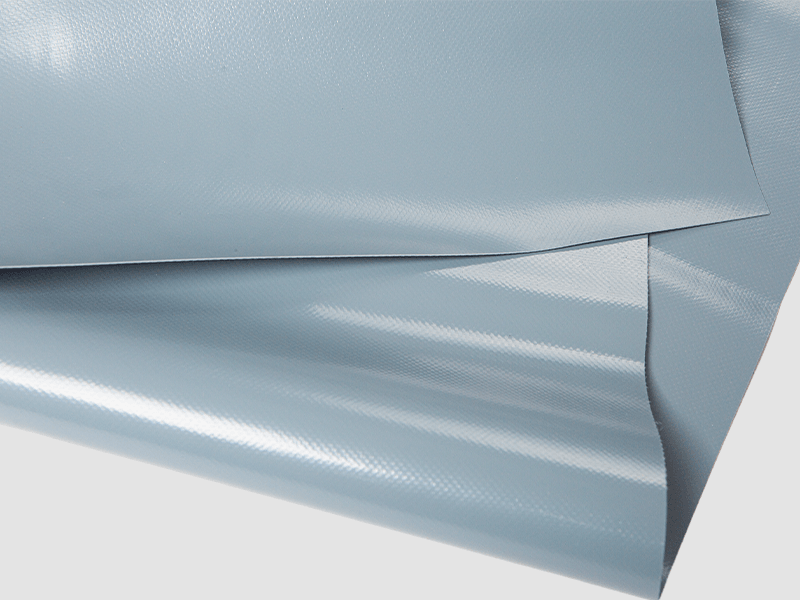

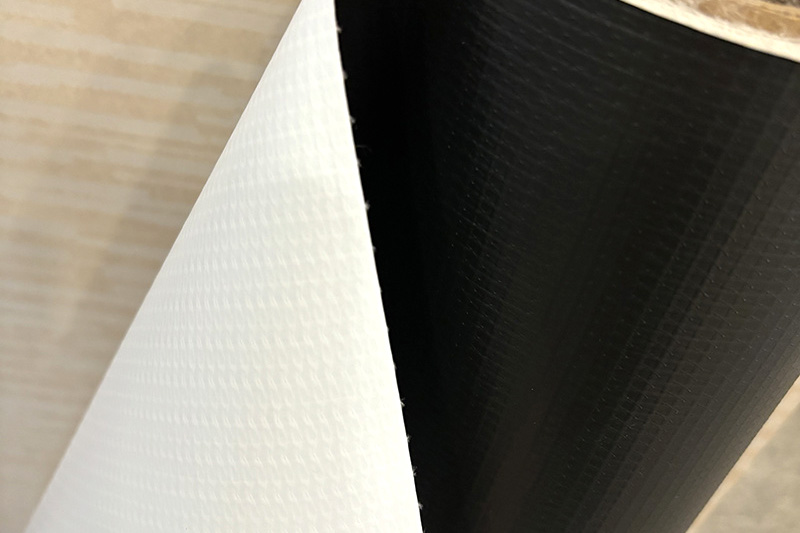

PVC coated tarpaulin is widely used across various industries for its versatility and protective qualities. One of the critical factors that influence its performance is the thickness of the PVC coating. Understanding how thickness affects durability and performance can help users make informed decisions based on their specific needs.

The thickness of the PVC coating plays a vital role in the durability of the tarpaulin. Thicker coatings generally provide enhanced resistance to wear and tear, contributing to a longer lifespan.

A thicker PVC layer improves the tarpaulin's ability to withstand tearing and abrasion, making it suitable for heavy-duty applications. In environments where the tarp is subject to rough handling or sharp objects, a thicker coating can significantly reduce the risk of damage.

Thicker PVC coatings offer better protection against harsh weather conditions. They are less likely to crack or become brittle under extreme temperatures, and they provide superior UV resistance, preventing degradation from prolonged sun exposure.

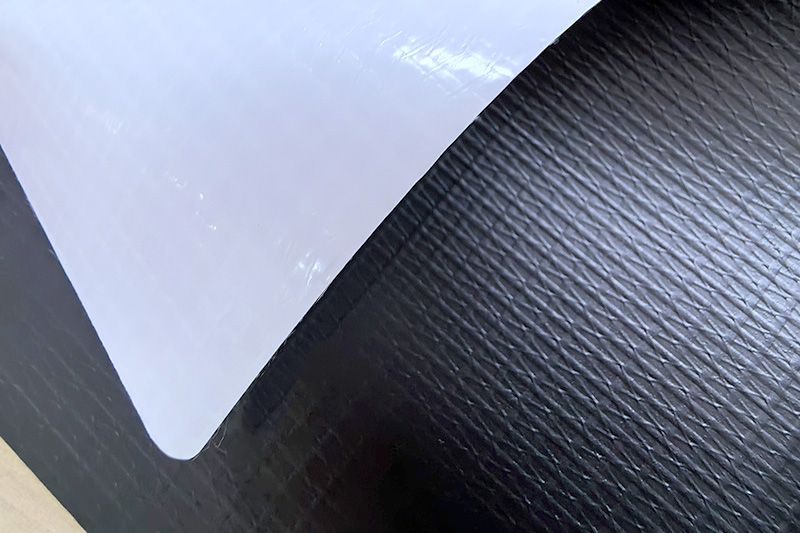

The thickness of the PVC coating also affects various performance characteristics of the tarpaulin:

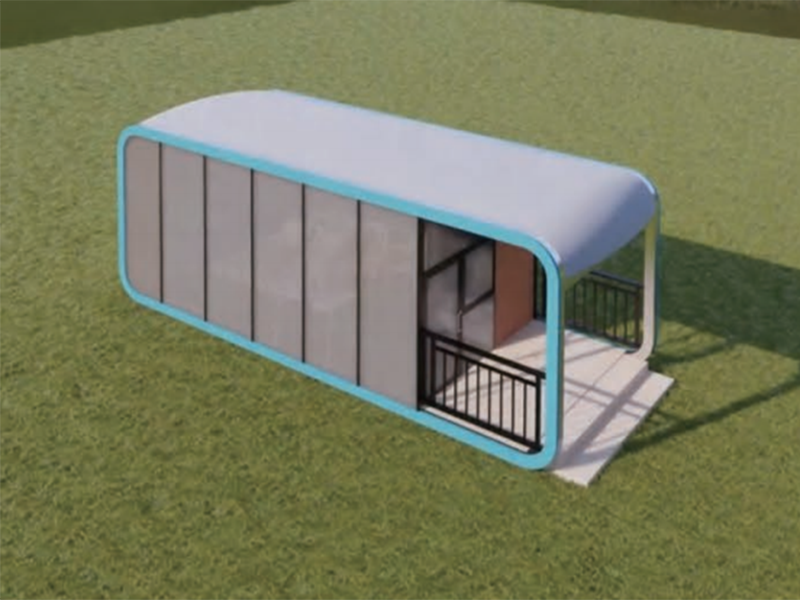

Thicker coatings enhance the waterproof properties of the tarpaulin. This is crucial for applications requiring reliable moisture protection, such as covering goods during transport or creating temporary shelters.

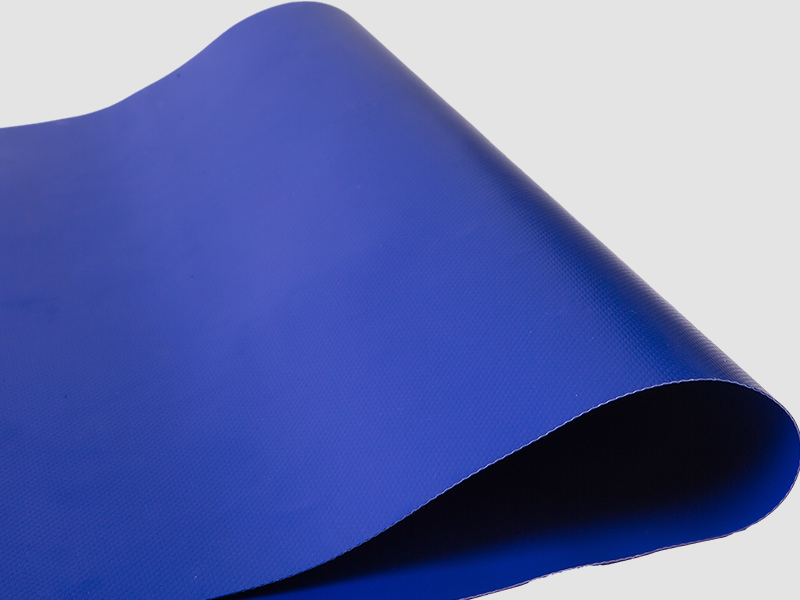

While a thicker PVC coating increases durability, it may also impact flexibility. Thicker tarpaulins can be less pliable, making them more challenging to fold or maneuver. This is an essential consideration for users who require ease of handling and storage.

Increased thickness generally results in a heavier tarpaulin. This can be beneficial for stability in windy conditions, but it may also make the tarp more cumbersome to transport and install. Users should balance the need for durability with the weight considerations based on their specific applications.

Thicker PVC coated tarpaulins typically come at a higher price point due to the increased material costs and enhanced performance characteristics. However, the initial investment may be offset by the longer lifespan and reduced need for replacements in demanding environments.

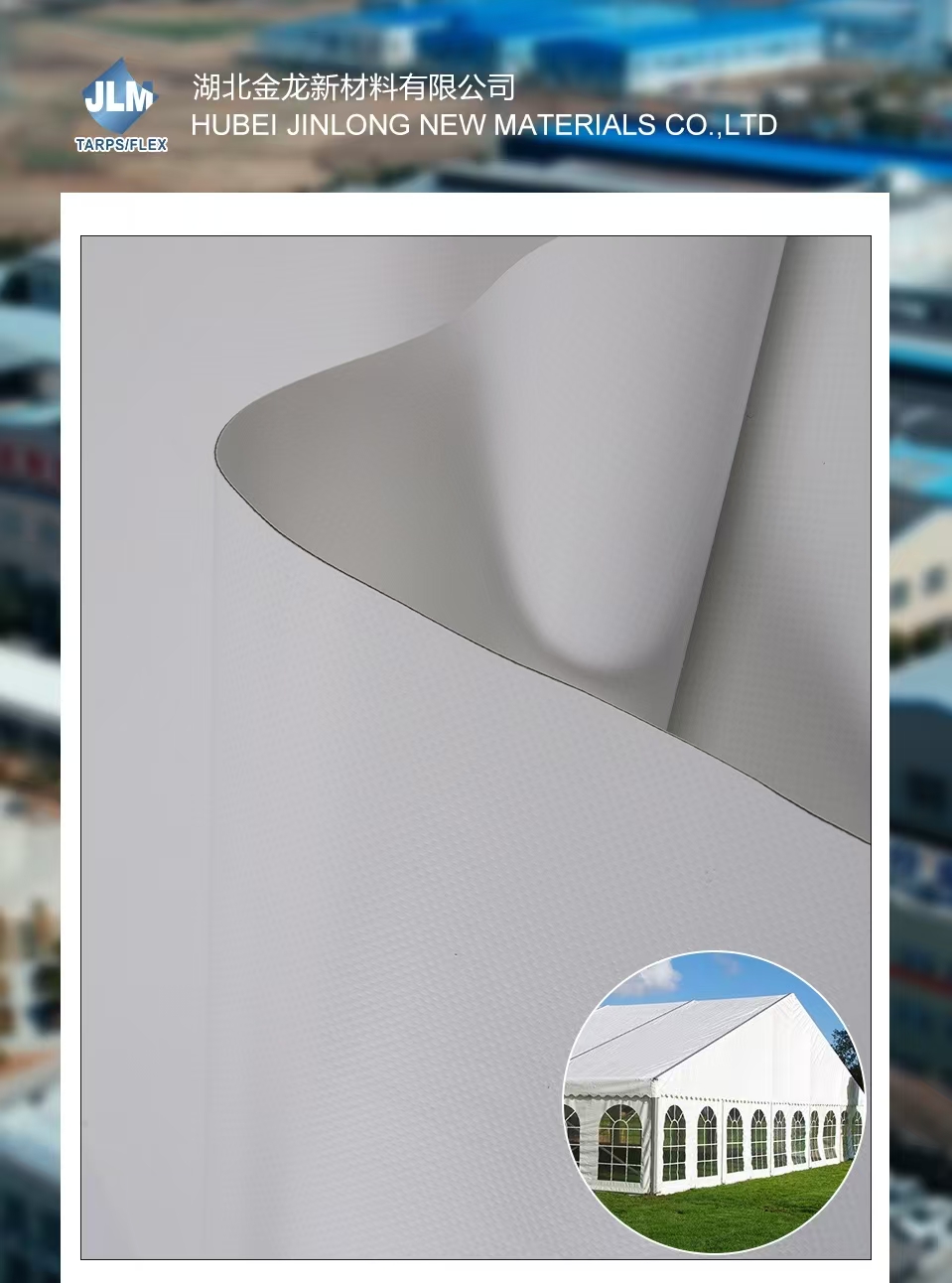

Choosing the right thickness depends on the intended application:

For uses such as truck covers, construction site barriers, or outdoor equipment protection, thicker tarpaulins (e.g., 700-900 gsm) are often recommended to withstand significant wear and environmental stress.

Thinner PVC coated tarpaulins (e.g., 300-500 gsm) may be suitable for lighter applications such as promotional banners, temporary shelters, or covers for equipment stored indoors.

The thickness of PVC coated tarpaulin significantly influences its durability and performance. Thicker coatings enhance durability, tear resistance, and waterproofing but may reduce flexibility and increase weight. When selecting a tarpaulin, it is crucial to consider the specific requirements of the application, balancing durability and performance with handling and cost. By understanding these factors, users can choose the most suitable PVC coated tarpaulin to meet their needs effectively.

English

English русский

русский Français

Français Español

Español