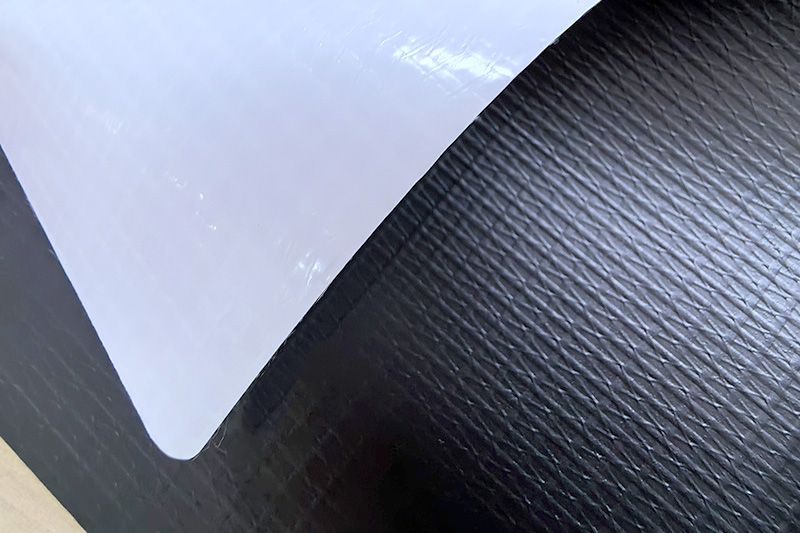

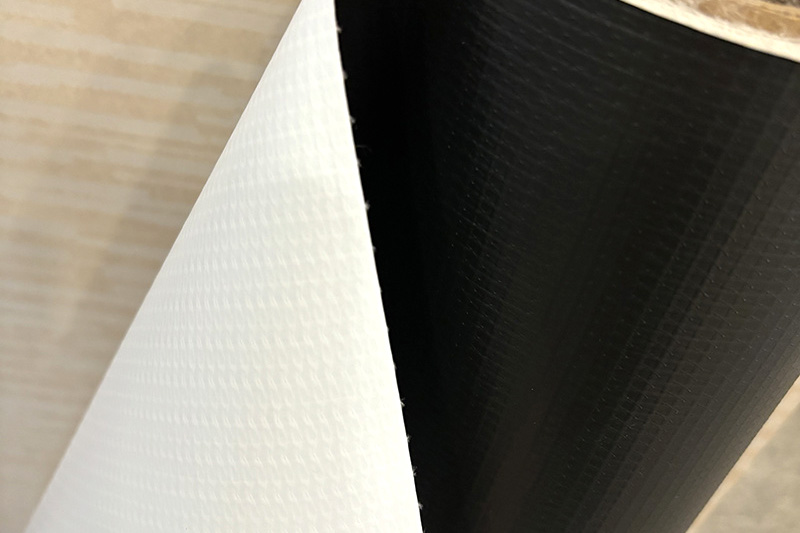

The thickness of PVC Laminated Tarpaulin is closely related to its waterproof performance, and the thickness directly affects the waterproof effect and durability of the tarpaulin under different use conditions.

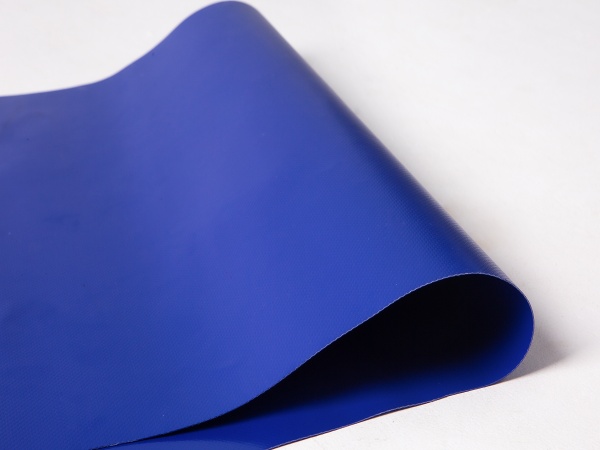

The thicker the PVC laminated tarpaulin, the better its waterproof barrier effect. The PVC coating itself has excellent impermeability, so a thicker coating can provide a stronger moisture barrier and reduce the risk of leakage under rain penetration or water pressure. Especially in heavy rain or long-term wet environments, thicker tarpaulins can better cope with water pressure and long-term water contact.

Thick coatings can effectively enhance the waterproof barrier of PVC tarpaulins, so that they can provide more lasting protection when facing water accumulation or humid environments, and are not easily penetrated by external forces or environmental factors. As the thickness increases, the tensile strength and water pressure resistance of the tarpaulin also increase. When the tarpaulin is subjected to heavy rainfall or water pressure, the thicker PVC layer can effectively prevent water droplets from penetrating to the back of the tarpaulin.

Thicker PVC laminated tarpaulins not only excel in waterproof performance, but also have higher wear and tear resistance. This makes it more durable in outdoor applications and able to withstand long-term wind and rain erosion and mechanical wear.

Thicker PVC coatings are less susceptible to scratches or wear, reducing the risk of water penetration caused by surface damage. This durability allows thick-coated tarpaulins to maintain a longer service life in harsh environments.

Increased thickness is usually accompanied by an increase in the overall strength of the tarpaulin, especially when encountering external physical impacts, thick tarpaulins are less likely to crack or tear, thereby further ensuring the integrity of the waterproof performance.

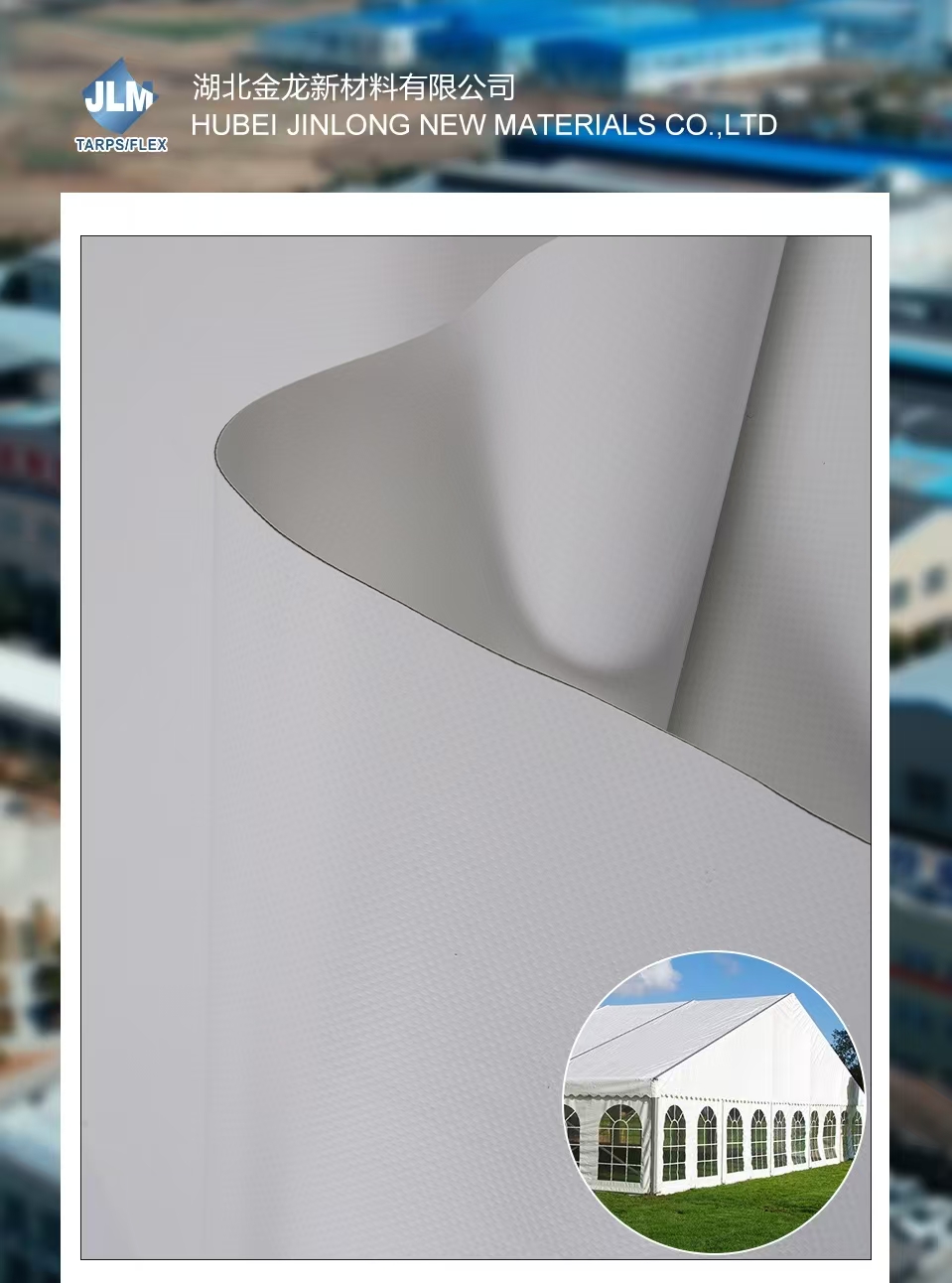

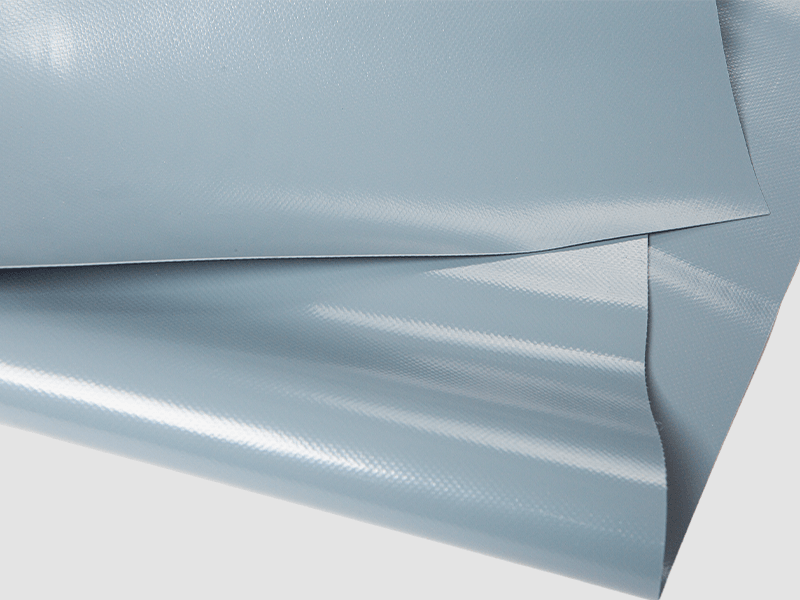

PVC coated tarpaulins are usually used in outdoor environments and are exposed to sunlight, rain, wind and sand for a long time. Thicker PVC tarpaulins have better weather resistance and perform better in terms of UV protection, corrosion resistance, acid and alkali resistance, etc. These improvements in weather resistance directly affect the durability of the waterproof effect.

Thick coatings can better resist the erosion of ultraviolet rays and avoid embrittlement and cracking of materials due to photodegradation, which ensures that the tarpaulin can still maintain its waterproof function when exposed to sunlight for a long time. Thicker PVC layers are not easily aged due to long-term wind and rain, ensuring that its waterproof function does not decrease over time.

The thickness of the PVC coated tarpaulin is also related to its performance under extreme temperature conditions. In high or low temperature environments, thick coatings can better maintain the physical properties of the material, avoid cracks or deformation caused by thermal expansion and contraction, and thus maintain its waterproof effect.

Thicker tarpaulins are not easy to soften or deform in high temperature environments, can maintain structural integrity, and will not have the risk of water seepage. In low temperature conditions, the thicker PVC layer can resist embrittlement or cracks caused by low temperatures, preventing the tarpaulin from losing its waterproof properties due to the cold.

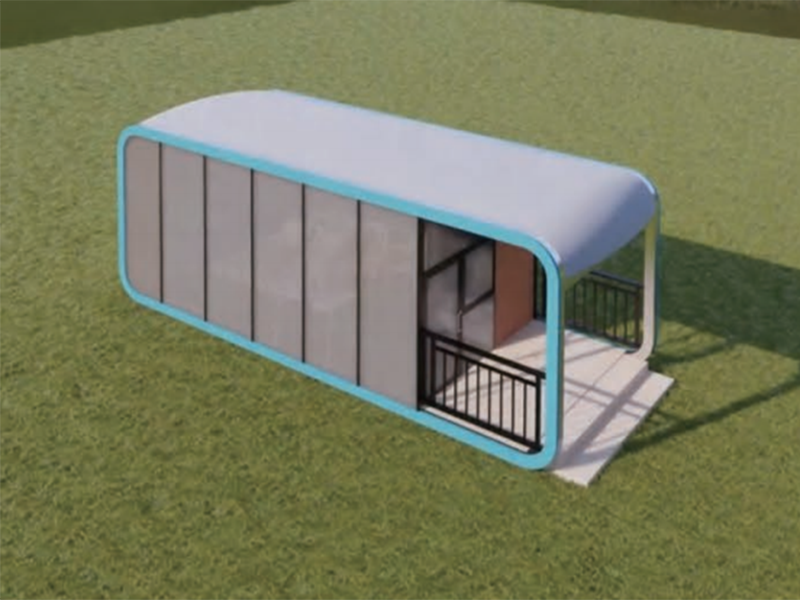

Depending on the application scenario, choosing the right thickness of PVC coated tarpaulin is the key to ensuring waterproof performance. In lightweight applications, such as general outdoor sunshade and billboard covering, thinner PVC tarpaulins can provide sufficient waterproof protection; while in heavy-duty application scenarios, such as truck transport tarpaulins, ship waterproof tarpaulins, etc., thicker PVC coated tarpaulins are more suitable.

In some scenarios where only short-term waterproofing is required or the environment is relatively mild, thinner PVC tarpaulins are sufficient. They excel in flexibility and portability, but the waterproof performance may be weakened in long-term use or extreme weather. In situations where strong waterproof protection is required, such as outdoor warehouse covers and large equipment protection tarpaulins, choosing thicker PVC coated tarpaulins can ensure that the tarpaulins can effectively prevent moisture from entering, whether in heavy rain, waterlogging or bad weather.

The thickness of PVC coated tarpaulin is closely related to its waterproof performance. The thicker the tarpaulin is, the better the waterproof effect is. The durability and tear resistance of the tarpaulin are also improved. However, the choice of thickness should also take into account the specific application scenario, which should not only meet the waterproof requirements, but also take into account the flexibility and convenience of use.

English

English русский

русский Français

Français Español

Español