The waterproofness and breathability of PVC inflatable boat fabric can perform differently depending on various factors, such as the design of the fabric, external environmental conditions, and usage.

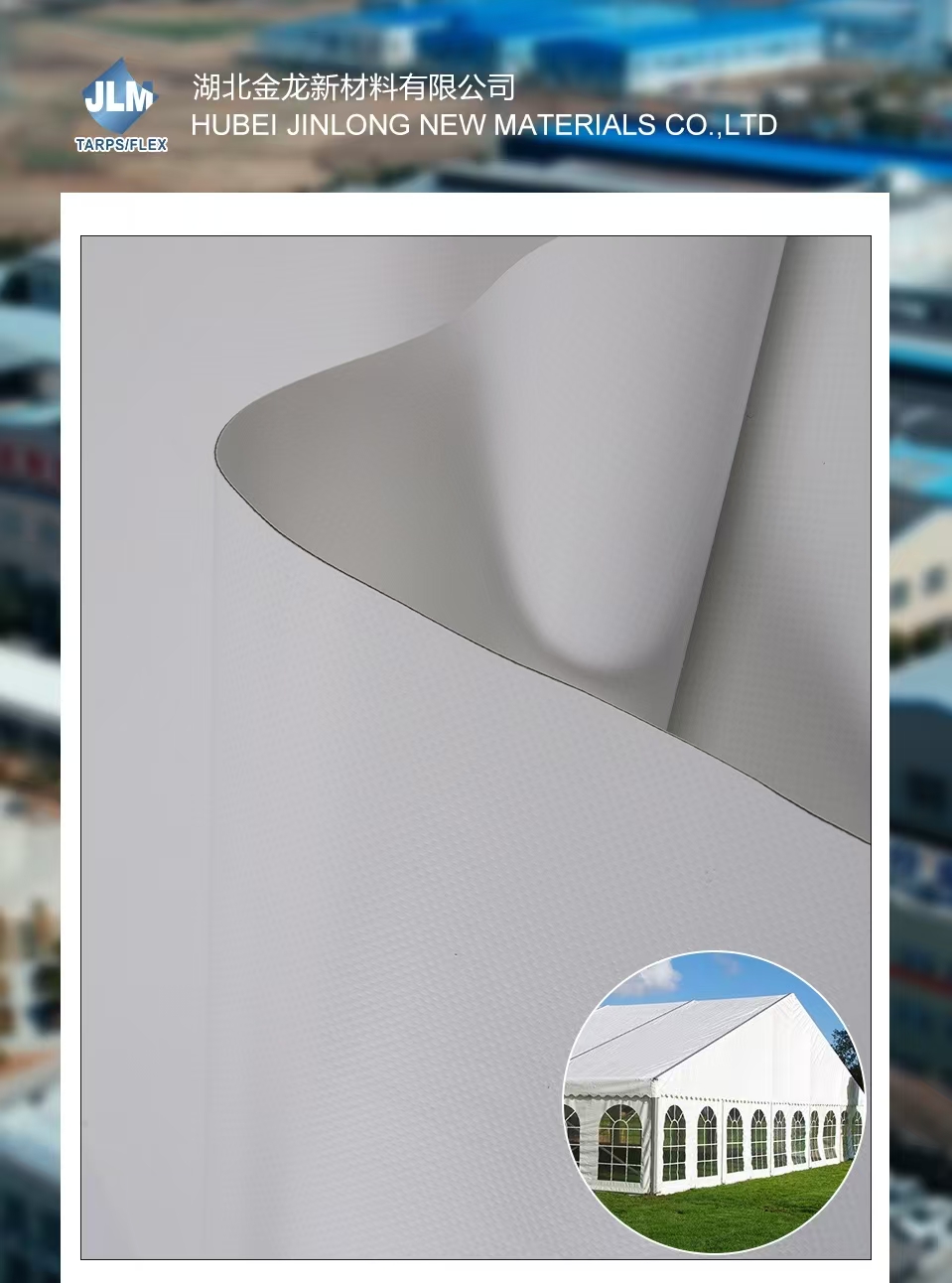

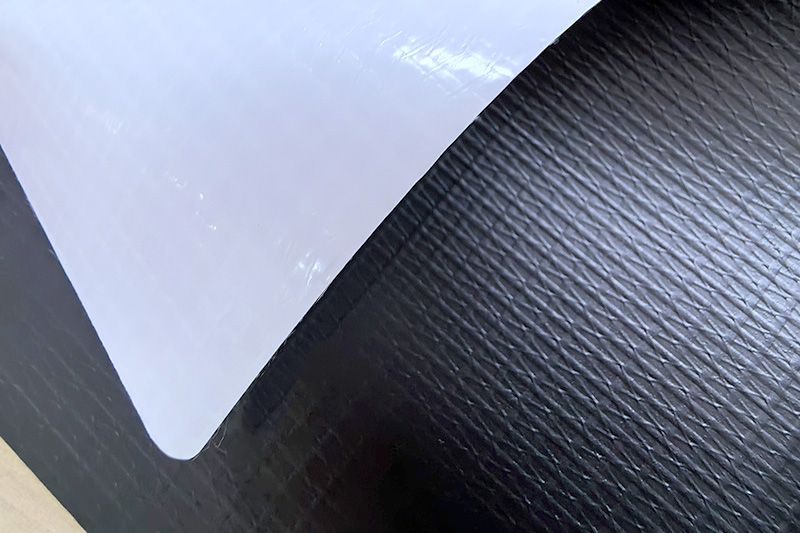

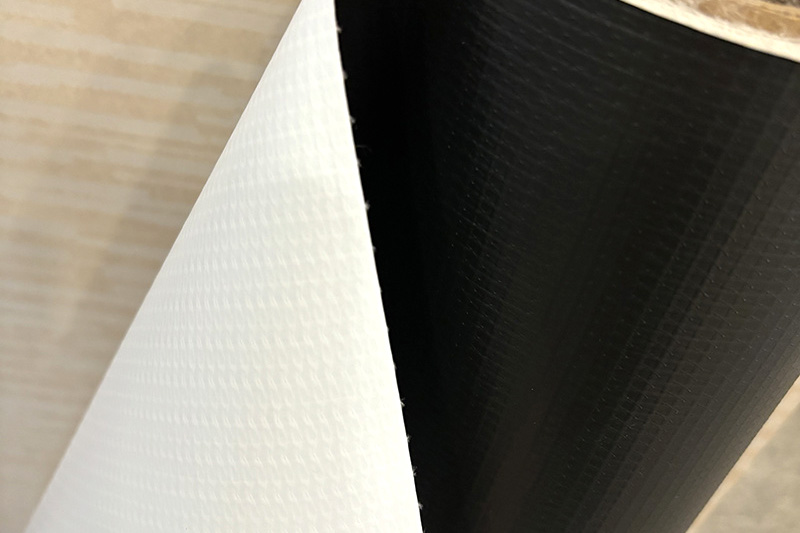

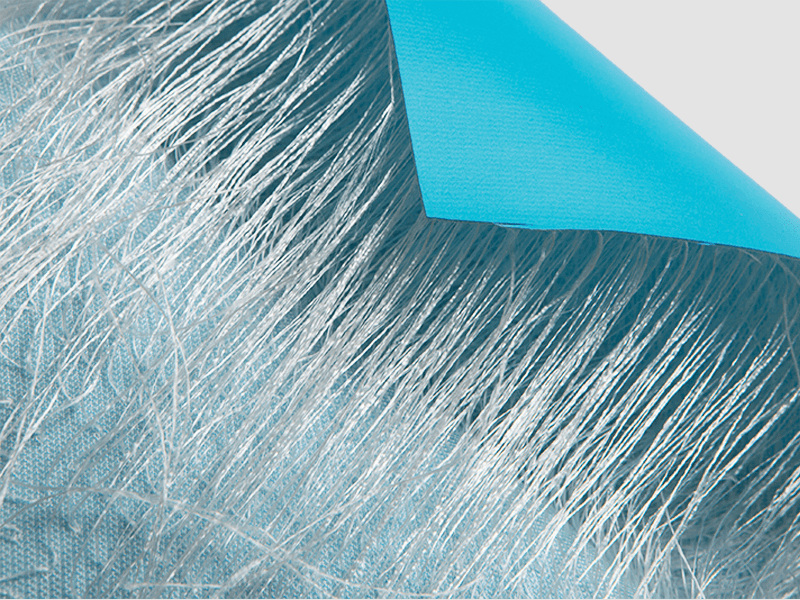

PVC fabric is inherently waterproof, making it an ideal choice for inflatable boats. The material itself is designed to resist water penetration, preventing leaks even when exposed to water for prolonged periods.Many PVC inflatable boat fabrics have a double-layered or laminated construction, which enhances waterproofing. Additional coatings such as polyurethane (PU) or polyester can be applied to increase resistance to water and improve durability.

In extreme conditions, such as heavy rainfall or when navigating through waves, PVC fabric performs well due to its resistance to water absorption and ability to shed water from the surface, keeping the boat's internal structure dry.Over time, prolonged exposure to UV rays, saltwater, or chemicals (like fuel or oil) can degrade the fabric’s waterproofing. Therefore, UV-resistant coatings are often applied to improve long-term durability.

PVC is a non-porous material, which means it doesn’t naturally allow air or moisture vapor to pass through. As a result, it doesn’t have significant breathability compared to some other fabrics (like nylon or polyester).In cold or humid conditions, this lack of breathability can lead to condensation buildup inside the boat, particularly if the temperature difference between the inside and outside of the boat is significant. Moisture may accumulate on the inside of the fabric or on surfaces inside the boat, which could cause discomfort or affect equipment.

Some inflatable boats designed with PVC fabrics might have additional features like vents or breathable panels in strategic locations to reduce condensation buildup and allow some air circulation, but these are limited.In warmer, dry conditions, the lack of breathability isn’t as much of an issue. The boat will stay dry inside and won’t trap as much moisture, which reduces discomfort. However, excessive heat can cause the fabric to become stiff or brittle over time, which is why some manufacturers apply UV-resistant and heat-resistant coatings to the fabric.

Exposure to saltwater can cause the PVC fabric to degrade over time if not cleaned and maintained properly. Salt can accelerate the breakdown of the fabric’s coatings, which may impact both waterproofness and durability.In hot and humid environments, condensation inside the boat is more likely, and the lack of breathability can contribute to a damp environment, especially if the boat is used in tropical or coastal regions.Ultraviolet (UV) radiation from the sun can weaken the fabric and its coatings, potentially reducing both waterproofness and durability. UV-resistant treatments are often applied to the fabric to prevent this degradation.

Hypalon (chlorosulfonated polyethylene) is another material commonly used for inflatable boats. While Hypalon has superior UV resistance, chemical resistance, and better long-term durability, it is generally less waterproof than PVC and may be more breathable, especially in some designs. However, Hypalon is also more expensive than PVC.Materials like polyester or nylon are often used in inflatable boat construction as the base fabric, with PVC or TPU (thermoplastic polyurethane) coatings for waterproofing. These materials tend to have better breathability but might not offer the same level of waterproofness and durability in extreme conditions as PVC.

PVC performs excellently in terms of waterproofing, making it a great material for inflatable boats in wet conditions, including saltwater environments. It effectively prevents water from soaking through and keeps the interior dry.PVC's breathability is quite low, which can lead to moisture buildup inside the boat under certain conditions, especially in humid or warm environments.

Ventilation features or special coatings can help, but PVC isn't inherently breathable.PVC is a solid choice for inflatable boats, especially for those who prioritize waterproofing and durability in wet conditions. However, the trade-off is reduced breathability, which can be mitigated by maintaining the boat properly and considering ventilation in the design.For use in particularly hot, humid, or tropical environments, additional precautions (e.g., ventilation systems or coatings) might be necessary to ensure comfort and prevent condensation.

English

English русский

русский Français

Français Español

Español