PVC Inflatable Fabric is known for its durability and high-performance characteristics, particularly in applications that require resistance to external stresses like tearing. The fabric’s tear resistance is a key performance attribute that determines its suitability for demanding environments, such as inflatable structures, boats, and other outdoor or industrial products. Here’s a detailed breakdown of the tear resistance and overall durability of PVC inflatable fabric:

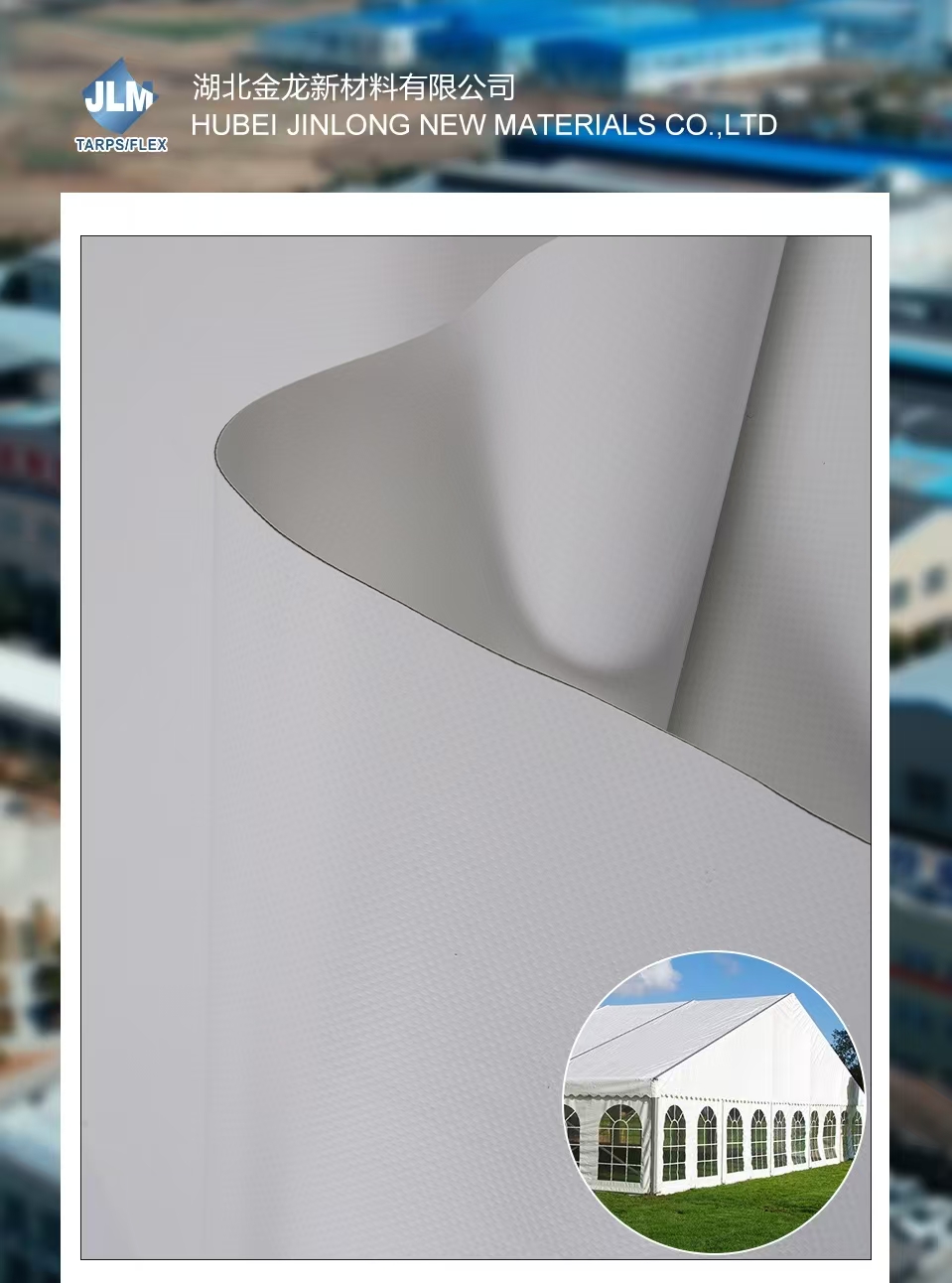

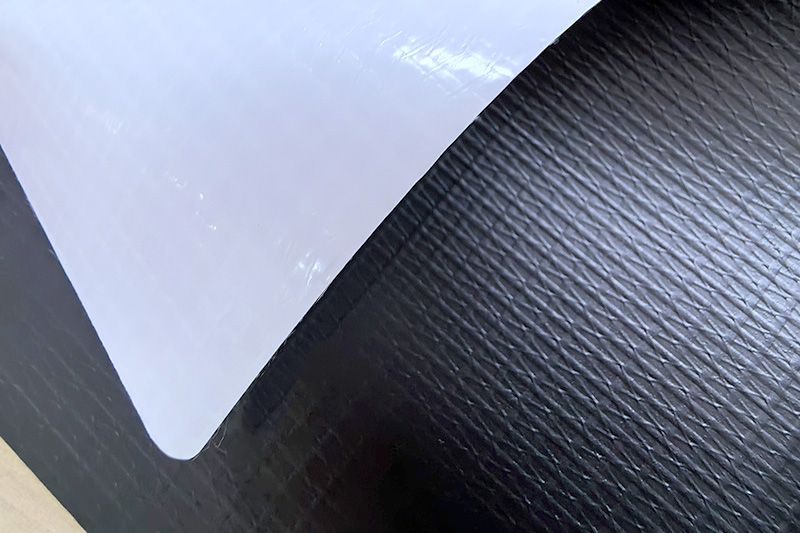

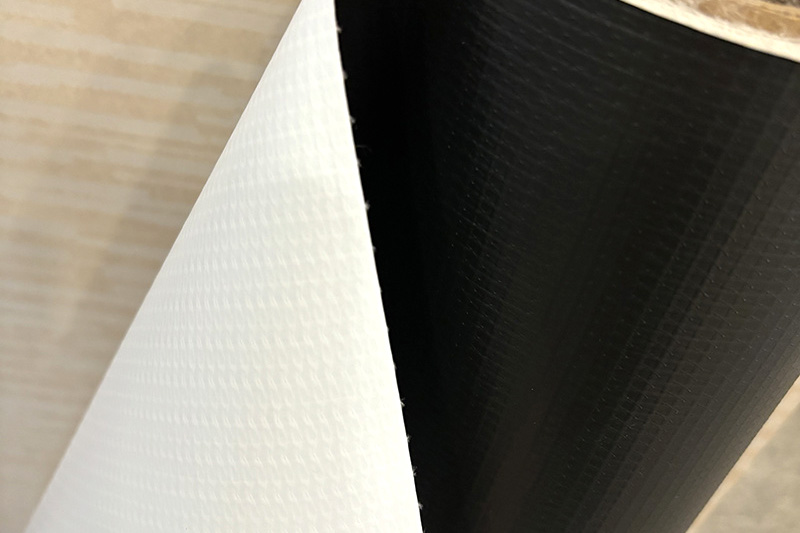

PVC inflatable fabric typically has a woven polyester or nylon base, which provides the structure and flexibility of the material. The base fabric is then coated with a PVC layer to offer waterproofing, durability, and resistance to environmental factors like UV radiation.

The weaving pattern and density of the base fabric play a significant role in tear resistance. Fabrics with a tighter weave (more threads per inch) tend to offer better tear resistance than looser weaves, as they can distribute the force more effectively over a larger surface area.

The PVC coating itself provides a layer of protection against tears, but its tear resistance is largely dependent on the thickness of the coating. A thicker PVC layer generally offers better tear resistance but may compromise flexibility.High-quality PVC inflatable fabric often uses reinforced threads (such as polyester or Kevlar) within the weave, which significantly enhances tear resistance. These fibers prevent the material from separating or breaking apart when subjected to stress, ensuring that the fabric doesn’t tear easily under pressure.

Some PVC inflatable fabrics feature multi-layer constructions where several layers of fabric are bonded together. This increases tear resistance by distributing any force or stress applied to the fabric, reducing the likelihood of one layer tearing and weakening the overall material.

While tear resistance refers to the initial ability to withstand a sharp object or force, tear propagation resistance involves preventing a small tear from spreading. PVC inflatable fabric is generally designed with high tear propagation resistance, meaning that once a tear forms, it is less likely to expand quickly. This is an essential feature, particularly for inflatable products, where small punctures or tears can jeopardize the integrity of the entire structure.

PVC fabrics often use heat sealing or welding techniques to bond seams, which can improve tear resistance at the joints. This method creates a strong, unified bond at the seam, preventing tears from starting at the stitch points, which are typically the weakest areas in non-welded fabrics.

PVC fabric’s tear resistance can be affected by temperature. In extremely low temperatures, PVC material becomes stiffer and more brittle, which makes it more prone to tearing under pressure. Similarly, very high temperatures can soften the material, reducing its tear resistance temporarily.

While PVC remains flexible at normal outdoor temperatures, extreme cold can cause the fabric to become rigid and less resistant to tearing from impacts or stress. It’s important to note that PVC fabric is generally not as resistant to tearing in extremely cold conditions (e.g., below freezing temperatures) as in moderate or warm climates.

In addition to tear resistance, PVC inflatable fabrics typically have abrasion-resistant properties that help prevent wear and tear from friction against rough surfaces. The more abrasion-resistant the fabric, the less likely it is to tear when exposed to surface contact or when dragged over abrasive ground or materials.Products like inflatable boats, rafts, and water sports equipment are often exposed to harsh conditions, including sharp rocks, submerged objects, and rough handling. PVC fabrics used in these products are designed to withstand such abrasions, which helps maintain the overall integrity of the fabric and prevent tears from forming.

One of the advantages of PVC inflatable fabric is that it is relatively easy to repair small tears. Special repair kits for PVC material are available that include adhesive patches or glues that bond well with the PVC surface, effectively sealing minor tears.However, if the tear is large or occurs along a seam, the repair process may be more involved, potentially requiring professional assistance to ensure the fabric's strength is restored.

PVC inflatable fabric is designed with exceptional tear resistance, thanks to its strong polyester or nylon base fabrics and the durable PVC coating. Its tear resistance is reinforced through a combination of factors including multi-layer construction, reinforced fibers, and seam welding. While the fabric can perform well in various conditions, it is important to consider temperature extremes, chemical exposure, and UV damage, as these can weaken its tear resistance over time. However, PVC inflatable fabric remains a durable and reliable material for applications requiring flexibility, water resistance, and protection against external damage.

English

English русский

русский Français

Français Español

Español