In terms of design and structure, PVC Tensile Tent Fabric improves its stability and safety in many ways.

PVC tensile tents usually adopt a tension structure design, which uses the high strength and elasticity of the material to maintain the stability of the tent under the action of wind and gravity. By pulling the fabric tight, external forces can be effectively dispersed and deformation can be reduced. The curved shape shows good aerodynamic properties under wind force, reducing the direct impact of wind pressure on the tent. This design can reduce wind resistance and thus improve stability.

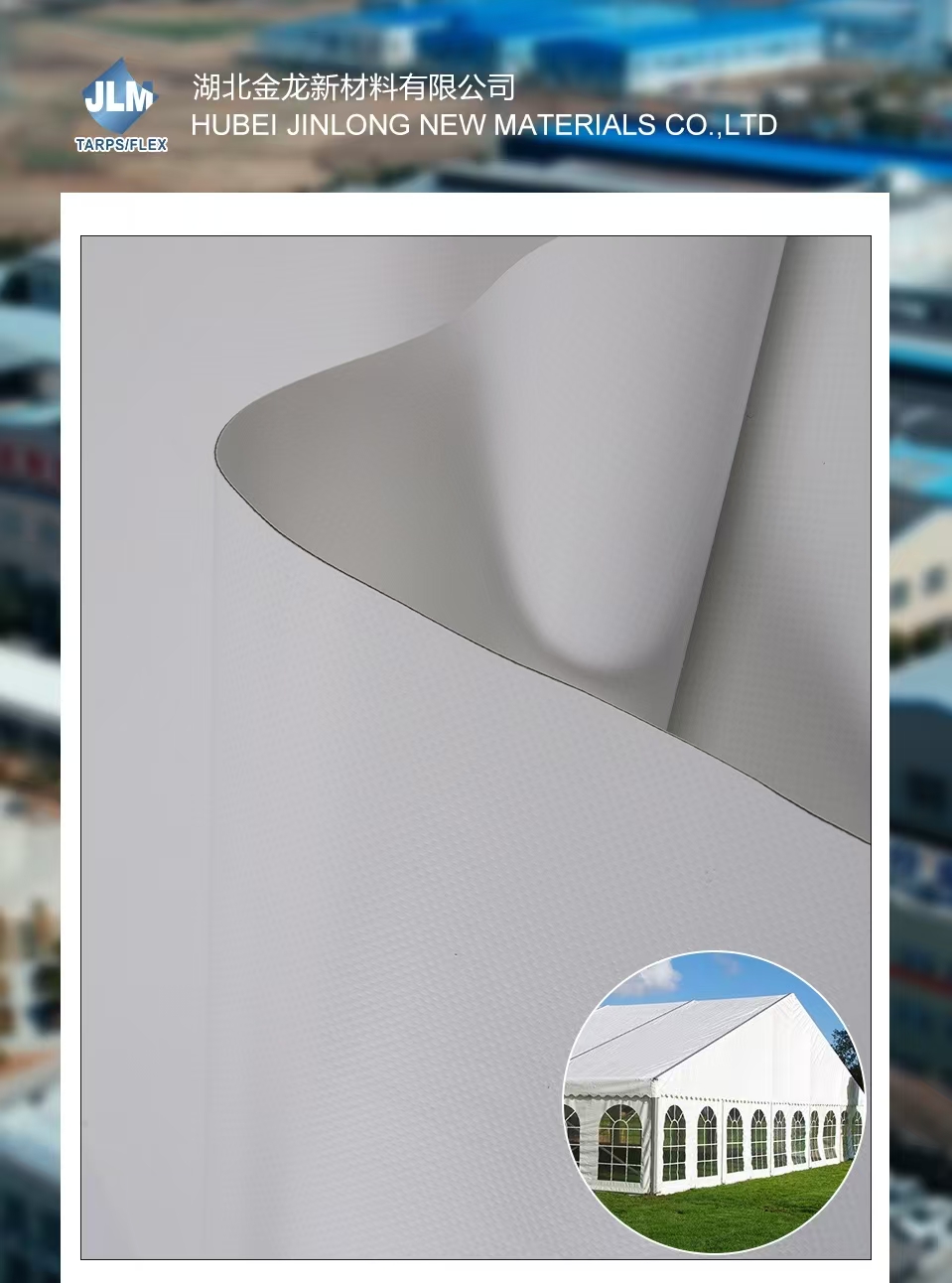

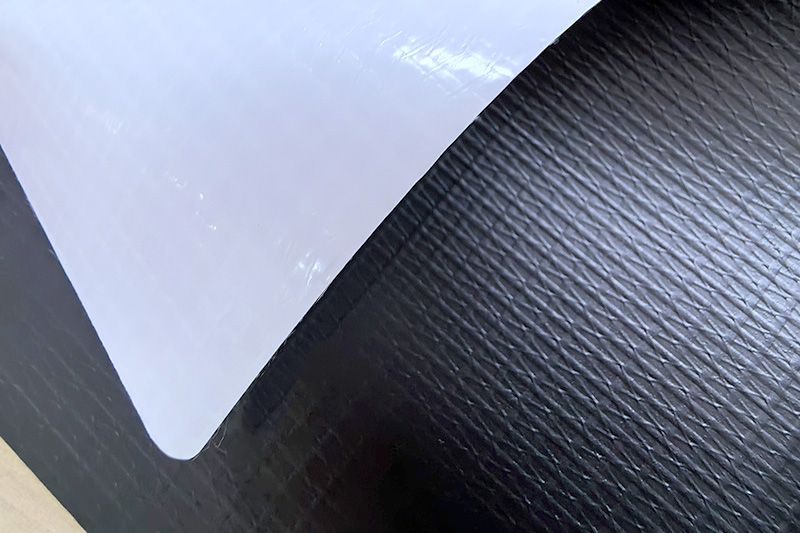

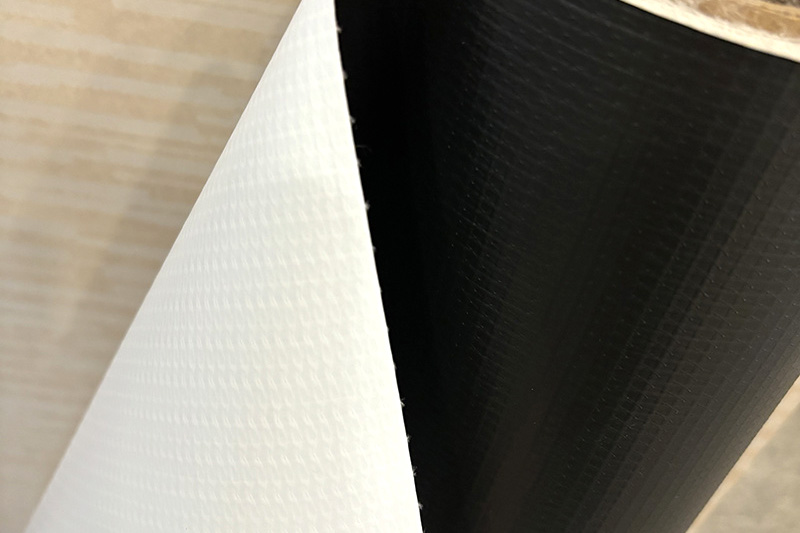

The use of high-strength PVC material can increase the durability and tear resistance of the tent. This material is not only waterproof, but also resistant to UV rays, extending the service life, so as to keep it safe in various weather conditions. Some high-end tents use a multi-layer material structure, with the outer layer providing waterproof and UV protection, while the inner layer may enhance breathability. This composite material design enhances the overall performance and safety of the tent.

PVC tensile tents are usually equipped with a sturdy support frame, such as aluminum alloy or steel brackets, which have good strength and stability. The support frame should be designed to withstand wind, snow weight and other external forces. The anchoring system of the tent usually adopts a variety of methods such as ground nails, ropes and weights to ensure the stability of the tent during use. By properly configuring the anchor points, the stability of the tent can be effectively increased to resist strong winds and adverse weather.

The PVC material itself has excellent waterproof properties, ensuring that the inside of the tent remains dry when used on rainy days. At the same time, the drainage system is taken into consideration during the design to avoid water accumulation from causing pressure on the tent structure. Good ventilation design can reduce the air pressure difference between the inside and outside of the tent, thereby reducing the structural pressure caused by wind pressure. The use of vents or window designs can effectively improve air circulation in the tent and reduce heat accumulation and water vapor.

The design and material selection of PVC stretch tents usually need to comply with relevant industry standards and safety regulations, such as fire protection standards and strong wind certification. Ensure the safety of the product under various environmental conditions. Before being put on the market, the tent undergoes multiple tests, including wind resistance, tear resistance and waterproof performance, to ensure its stability and safety in actual use.

PVC Tensile Tent Fabric improves its stability and safety through reasonable structural design, material selection, support system and effective management of wind and rain. These design considerations ensure the tent's reliability in a variety of environmental conditions, making it an ideal choice for outdoor activities and temporary buildings. Through safety tests that meet industry standards, the product's market competitiveness and consumer trust are further enhanced.

English

English русский

русский Français

Français Español

Español