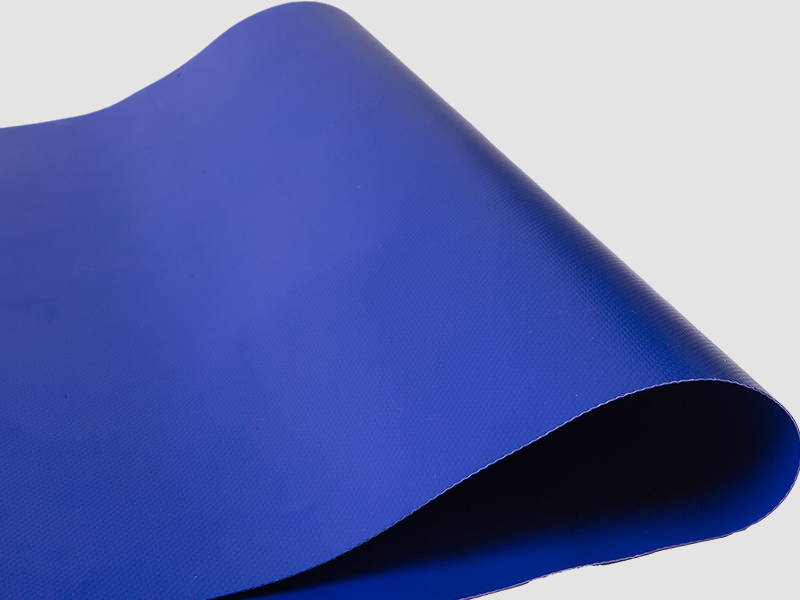

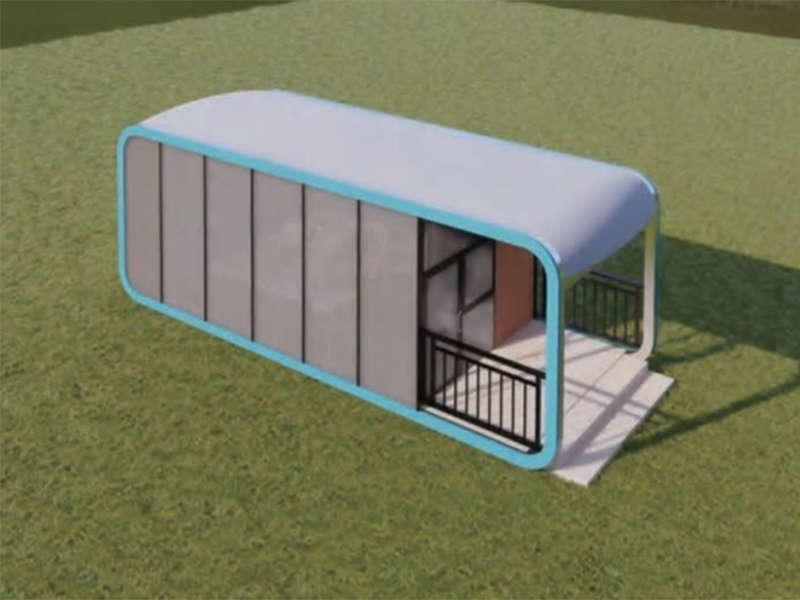

PVC Tensile Fabric is a high-performance composite material widely used in the fields of construction, industry and decoration. In order to ensure its performance stability and long-term reliability in actual use, strict control is required in the production process from raw material selection, process control, quality inspection to finished product management. The following are specific measures:

Quality control of raw materials

Selection and inspection of substrates

The substrate of PVC tensile fabric is usually high-strength polyester fiber or glass fiber. The following characteristics of the substrate must be ensured when purchasing:

Tensile strength: The tensile strength of the substrate directly affects the mechanical properties of the final product.

Uniformity: The weaving density and fiber distribution of the substrate should be uniform to avoid local weak points.

Durability: The substrate should have good chemical corrosion resistance and aging resistance.

Strict physical property tests (such as tensile strength and elongation at break) are carried out on each batch of substrates to ensure that they meet the design requirements.

Selection of coating materials

PVC resin is the main coating material, and plasticizers, stabilizers, UV absorbers and other additives are usually added. The proportion of these additives directly affects the flexibility, weather resistance and fire resistance of the coating.

Select high-quality PVC resins and additives, and conduct qualification audits on suppliers to ensure the stability and consistency of raw materials.

Raw material storage

Raw materials should be stored in a dry and ventilated environment, away from moisture or UV exposure to avoid affecting their performance.

Optimization and control of production processes

Substrate pretreatment

Before coating, clean and surface treat the substrate (such as corona treatment or chemical treatment) to improve the adhesion between the substrate and the PVC coating.

Ensure the consistency of the pretreatment process, such as the treatment time, temperature and chemical concentration should be strictly controlled.

Coating process

Uniformity of coating thickness: Ensure consistent coating thickness through precision coating equipment (such as blade coater or roller coater). Too thin coating may result in insufficient waterproof performance, while too thick may affect flexibility and cost.

Layered coating technology: For high-performance PVC stretch fabrics, a multi-layer coating process (such as base coat, intermediate functional layer and surface protective layer) can be used, and the functions of each layer should be clear and compatible with each other.

Curing conditions: The curing process after coating (such as heating temperature and time) is crucial to the performance of the product. Insufficient curing may result in poor coating adhesion, while overcuring may make the material brittle.

Tension control

During the production and coating process of the fabric, proper tension control is maintained to avoid deformation of the substrate or uneven coating.

Use an automated tension control system to monitor and adjust the tension in real time to ensure product consistency.

Environmental control

The temperature and humidity of the production workshop should be kept within a reasonable range (such as temperature 20-25℃, humidity 50%-60%) to avoid the impact of environmental factors on coating quality and substrate performance.

Online monitoring and feedback control

Real-time monitoring system

Install sensors and monitoring equipment in key processes to monitor production parameters (such as coating thickness, temperature, tension, etc.) in real time. Once an abnormality is found, adjust the process parameters immediately.

For example, use an infrared thermometer to monitor temperature changes during the curing process to ensure stable curing conditions.

Automation equipment

The introduction of automated production lines (such as automatic coating machines, intelligent calenders) can reduce human errors and improve production efficiency and product accuracy.

Automation equipment can also achieve precise control in batch production to ensure consistent product quality for each batch.

With the continuous changes in market demand and technological advancement, the PVC stretch fabric industry will usher in a higher level of development in the future.

English

English русский

русский Français

Français Español

Español